- myBITZER

- BITZER SOFTWARE

-

ePARTS

ePARTS makes finding the appropriate spare parts for our products fast and easy. The parts are listed according to the model range and appear as a simple zoomable expanded-view drawing. The software is free of charge. As a direct BITZER customer registered at myBITZER, you benefit from additional advanced features – for example, the ability to view online prices of individual spare parts.

ePARTS makes finding the appropriate spare parts for our products fast and easy. The parts are listed according to the model range and appear as a simple zoomable expanded-view drawing. The software is free of charge. As a direct BITZER customer registered at myBITZER, you benefit from additional advanced features – for example, the ability to view online prices of individual spare parts.

- Documentation

- Contact

- Germany (de)

-

Germany (de)

-

Please select country and language:

-

Europe

- Austria / de

- Belarus / en

- Belgium / fr

- Bosnia-Herzegovina / en

- Bulgaria / en

- Croatia / en

- Cyprus / en

- Czech Republic / en

- Denmark / en

- Denmark / dk-en

- Estonia / en

- Finland / en

- France / fr

- Germany / de

- Greece / en

- Hungary / en

- Iceland / en

- Ireland / en

- Italy / it

- Latvia / en

- Lithuania / en

- Luxembourg / fr

- Malta / en

- Netherlands / en

- Norway / en

- Poland / en

- Portugal / pt

- Romania / en

- Russia / ru

- Serbia & Montenegro / en

- Slovakia / en

- Slovenia / en

- Spain / es

- Sweden / en

- Switzerland / de

- Turkey / en

- Ukraine / en

- United Kingdom / en

-

America

- Argentina / es

- Barbados / en

- Belize / en

- Bolivien / es

- Bonaire, Sint Eustatius and Saba / en

- Brazil / pt-br

- Canada / en

- Canada / fr

- Caribbean / en

- Chile / es

- Colombia / es

- Costa Rica / es

- Cuba / es

- Curacao / en

- Dominican Republic / es

- Ecuador / es

- El Salvador / es

- Grenada / es

- Guatemala / es

- Haiti / fr

- Honduras / es

- Jamaika / en

- Mexico / es

- Netherlands Antilles / en

- Nicaragua / es

- Panama / es

- Paraguay / es

- Peru / es

- Puerto Rico / en

- Puerto Rico / es

- Sint Maarten (Dutch part) / en

- Trinidad & Tobago / en

- U.S.A. / us

- Venezuela / es

-

Asia

- Bahrain / en

- Bangladesh / en

- Brunei / en

- China / zh

- Hong Kong SAR of China / en

- India / in-en

- India / en

- Indonesia / en

- Iran / en

- Israel / en

- Japan / ja

- Jordan / en

- Kuwait / en

- Lebanon / en

- Malaysia / en

- Maldives / en

- Myanmar / en

- Oman / en

- Pakistan / en

- Philippines / en

- Qatar / en

- Saudi Arabia / en

- Singapore / en

- South Korea / ko

- Sri Lanka / en

- Syria / en

- Thailand / en

- U.A.E. / en

- Vietnam / en

- Yemen / en

-

Africa

- Algeria / fr

- Angola / pt

- Botswana / en

- Cameroon / fr

- Cameroon / en

- Democratic Republic of Congo (DRC) / fr

- Djibouti / fr

- Egypt / en

- Equatorial Guinea / es

- Equatorial Guinea / pt

- Equatorial Guinea / fr

- Ethiopia / en

- Ghana / en

- Kenya / en

- Lesotho / en

- Libya / en

- Madagascar / fr

- Malawi / en

- Mauritius / en

- Morocco / en

- Mozambique / pt

- Namibia / en

- Nigeria / en

- Reunion / fr

- Senegal / fr

- Seychelles / en

- Seychelles / fr

- South Africa / en

- Sudan / en

- Swaziland / en

- Tanzania / en

- Tunisia / en

- Uganda / en

- Zambia / en

- Zimbabwe / en

-

Australia

-

- Australia / en

- New Zealand / en

-

CSH2T

CSH2T

The compact screw compressors of the CSH2T95 version are designed for high-temperature heat pumps using R1233zd(E) and R245fa refrigerants. These models enable fluid outlet temperatures of up to 120 °C and are developed for process heating systems such as pressurised water heating or low-pressure steam generation. The CSH2T series differs by adapting all essential components to the elevated temperature level. The compressors are only available in combination with VARIPACK frequency converters for speed control. An advanced compressor protection device (SE-i1) monitors and records operating parameters such as pressures and temperatures in real time.

CSH2T95 compressors are only available to OEM system manufacturers with experience in building high-temperature heat pumps.

Refrigerants

- R1233zd(E), Safety Class A1

- R245fa, Safety Class B1

Product Range

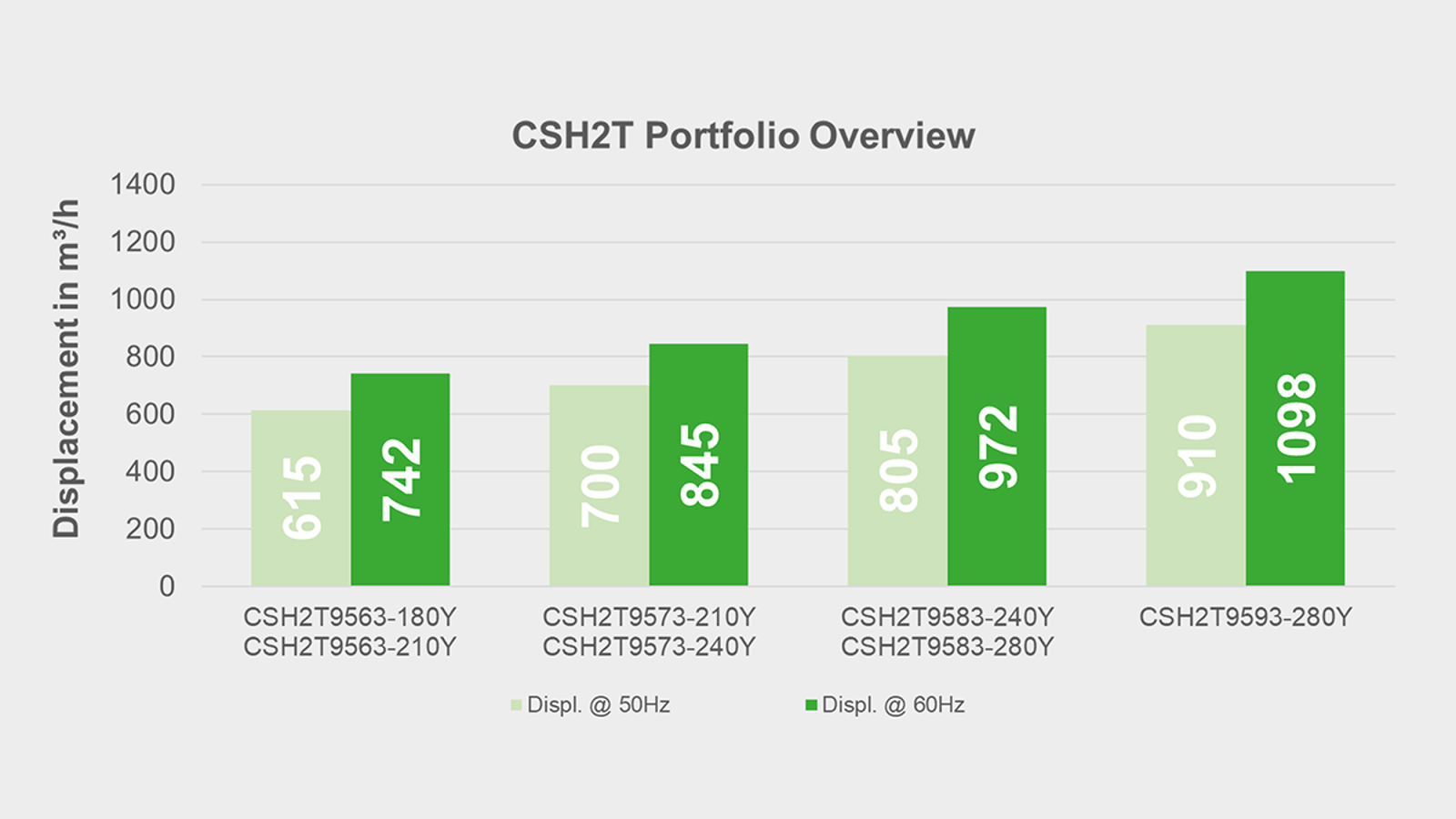

- 4 displacement volume levels

- Volumetric flow rate: 615 to 910 m³/h at 50 Hz

- Operation up to 60 Hz possible in combination with VARIPACK frequency inverter

Certifications

- CE incl. UKCA

Applications

Heat pumps for process heating and district heating networks with useful temperatures up to 120 °C, e.g. for:

- Pressurised water heating

- Thermal oil heating

- Low-pressure steam generation

Industries

- Food and beverage industry

- Automotive and mechanical engineering industry

- Chemical and pharmaceutical industry

- Pulp and paper industry

- Waste and environmental technology

- And many more…

Documentation

Highlights

- Heating capacities of over 1 MW per compressor achievable – depending on operating conditions

- Optimised design and components for high-temperature applications – based on the CSH.5 series: Compressor design adapted to the temperature level, e.g.:

- Suction gas-cooled built-in motor in high-temperature version

- High-temperature rolling bearings

- High-temperature refrigeration oil B-CE500

Capacity Control

- Speed control with VARIPACK frequency inverter Enables a wide modulation range

- Perfect adaptation of heating capacity to system demand

- Wide range of models up to 480 A rated output current

Compressor Protection Device

- Advanced compressor protection device SE-i1 – Full Sensor Kit (FSK)

- Monitoring of operating limits including: Discharge gas temperature

- Minimum oil level

- High and low pressure

- Data logging

- Communication via Modbus RTU/Bluetooth

- Integration via BITZER BEST SOFTWARE

- And much more ...

Extensive Application Range

- Wide evaporation temperature range from +20 to +80 °C enables a variety of possible heat sources

- High temperature lift of up to 85 K achievable

- Evaporation temperature up to 125 °C possible in continuous operation

Reduced Lifecycle Costs

- Industry-leading performance figures

- Long service life thanks to very robust bearings and low-vibration design

- Low maintenance costs due to service-friendly construction

- BITZER’s global service network ensures worldwide availability of spare parts

Reliability

- All compressors are tested at the factory

- BITZER supports safe system operation through comprehensive customer qualification and technical consulting

- Comprehensive protection via SE-i1 compressor protection device

- Safe system shutdown via VARIPACK

Compressor Accessories

- Suction and discharge gas shut-off valves

- Adapter and shut-off valve for ECO connection

- Vibration dampers

System Accessories

- Shell-and-tube condensers

- Shell-and-tube evaporators

- Liquid receivers

-

Features

Highlights

- Heating capacities of over 1 MW per compressor achievable – depending on operating conditions

- Optimised design and components for high-temperature applications – based on the CSH.5 series: Compressor design adapted to the temperature level, e.g.:

- Suction gas-cooled built-in motor in high-temperature version

- High-temperature rolling bearings

- High-temperature refrigeration oil B-CE500

Capacity Control

- Speed control with VARIPACK frequency inverter Enables a wide modulation range

- Perfect adaptation of heating capacity to system demand

- Wide range of models up to 480 A rated output current

Compressor Protection Device

- Advanced compressor protection device SE-i1 – Full Sensor Kit (FSK)

- Monitoring of operating limits including: Discharge gas temperature

- Minimum oil level

- High and low pressure

- Data logging

- Communication via Modbus RTU/Bluetooth

- Integration via BITZER BEST SOFTWARE

- And much more ...

-

Benefits

Extensive Application Range

- Wide evaporation temperature range from +20 to +80 °C enables a variety of possible heat sources

- High temperature lift of up to 85 K achievable

- Evaporation temperature up to 125 °C possible in continuous operation

Reduced Lifecycle Costs

- Industry-leading performance figures

- Long service life thanks to very robust bearings and low-vibration design

- Low maintenance costs due to service-friendly construction

- BITZER’s global service network ensures worldwide availability of spare parts

Reliability

- All compressors are tested at the factory

- BITZER supports safe system operation through comprehensive customer qualification and technical consulting

- Comprehensive protection via SE-i1 compressor protection device

- Safe system shutdown via VARIPACK

-

Accessories

Compressor Accessories

- Suction and discharge gas shut-off valves

- Adapter and shut-off valve for ECO connection

- Vibration dampers

System Accessories

- Shell-and-tube condensers

- Shell-and-tube evaporators

- Liquid receivers