Mount electronic cooling unit valve group

Screw in electronic cooling unit valve group by hand at upper and lower joints

Make sure the that the 2 O-rings on back of the flange stay in position!

Attach flange

- 6 mm hexagon spanner with ball head + extension

Mount flange with torque spanner

- 6 mm hexagon spanner with ball head + extension

- Torque spanner

- Tightening torque: 23 Nm

Risk of damage to the component.

Tighten screws crosswise in at least 2 steps to the prescribed tightening torque.

Mount electronic cooling unit valve group

- One joint at upper electronic expansion valve:

- Spanner SW 22 (counterhold with SW 19 spanner)

- Tightening torque: 50 Nm

- Two joints at lower shut-off valve:

- Spanner SW 30 (counterhold with SW 22 spanner)

- Tightening torque: 85Nm

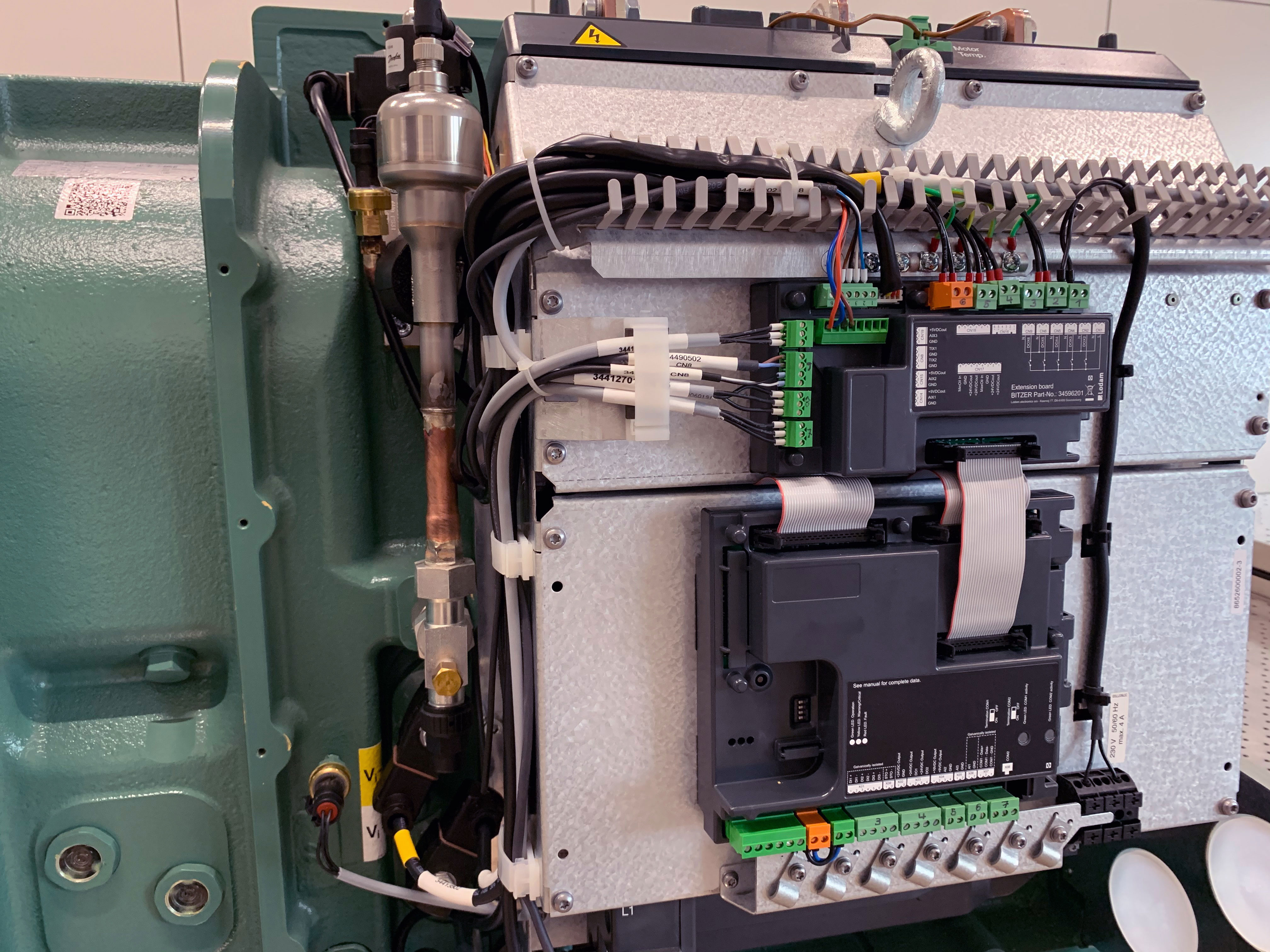

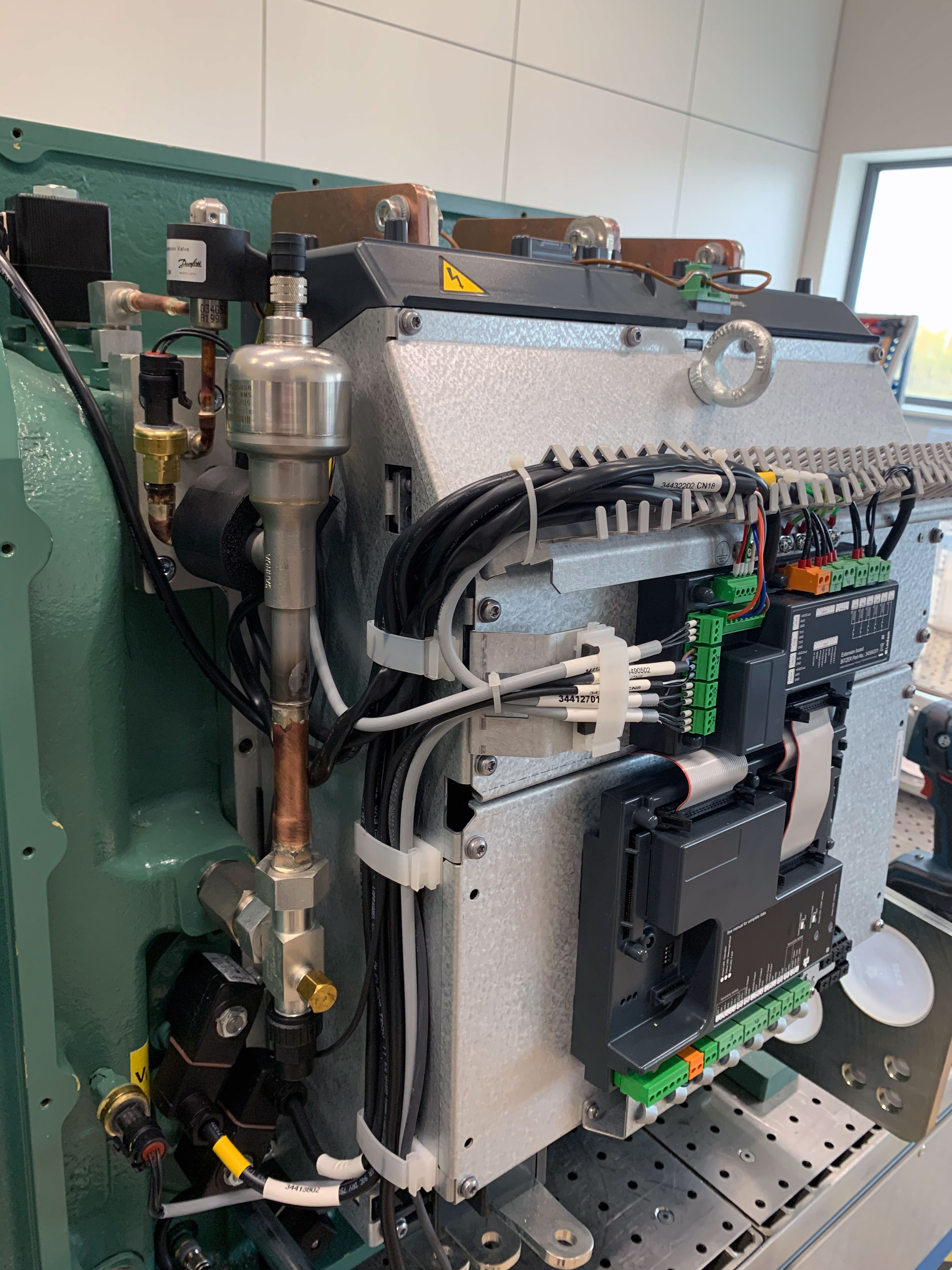

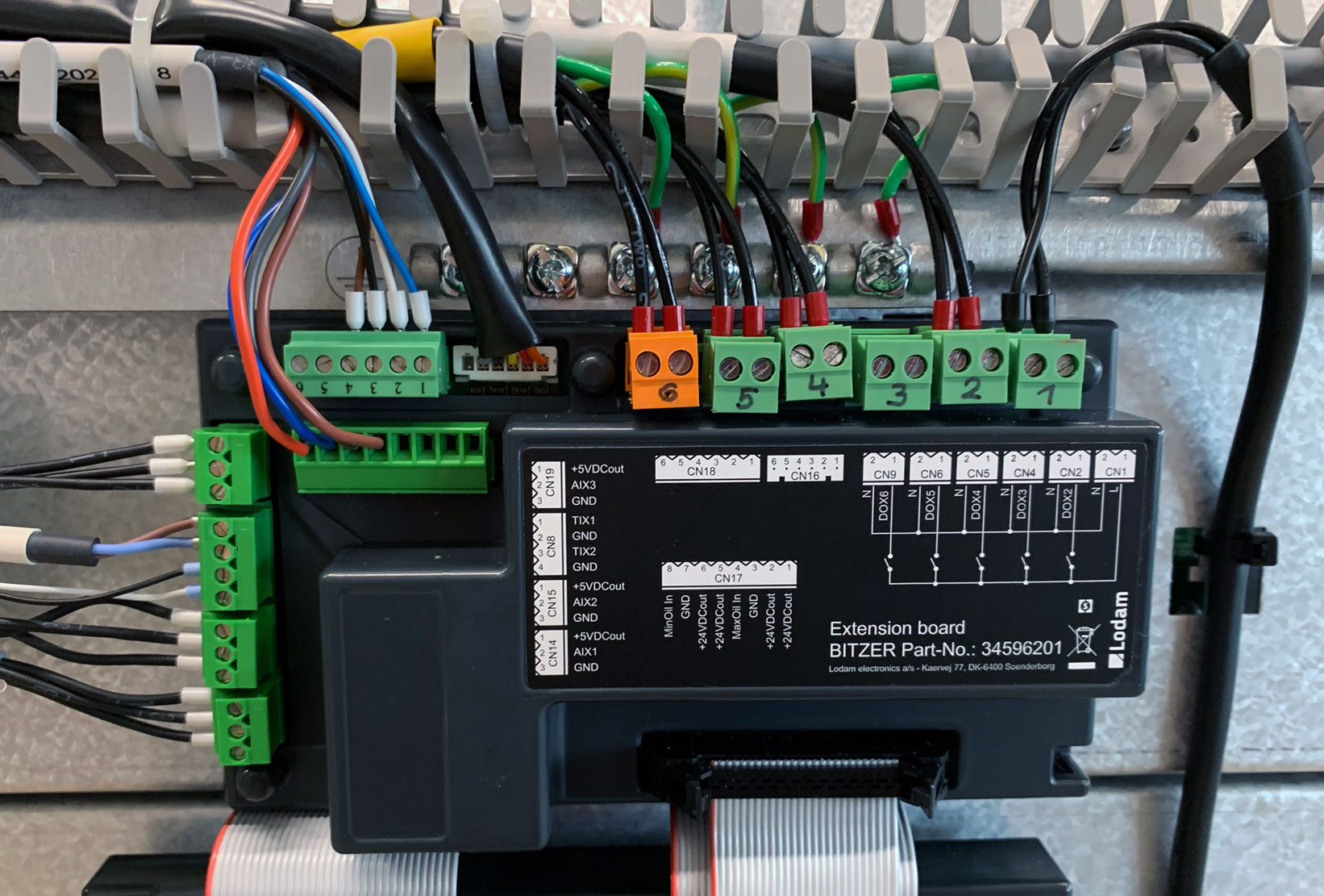

Terminal assignment at the extension board after the electronic cooling unit valve group has been mounted

- Reconnect all cables and components of the electronic cooling unit valve group.

- Reconnect all terminals and screw the cable cores of the temperature sensor to terminal CN8.

- For detailed description see video mounting instructions SW-164.

Terminal | Connected component |

|---|---|

CN1 | Voltage supply for solenoid valves and oil heater |

CN2 | Oil heater |

CN4 | Liquid injection |

CN5 | Solenoid valve “FI cooling” |

CN6 | Solenoid valve "Vi silder -" |

CN9 | Solenoid valve "Vi slider +" |

CN16 | Coil of electronic expansion valve for cooling plate |

CN18 | Electronic evaporator pressure valve for cooling plate |

CN17 | Oil monitoring OLC-D1-S min (5-8) and max (1-4, not connected in the picture) |

CN19 | Pressure transmitter at cooling plate outlet |

CN8 | Oil temperature sensor (1+2); Temperature sensor at cooling plate outlet (3+4) |

CN15 | Low pressure transmitter |

CN14 | High pressure transmitter |

Mounting and electrical connection of the complete electronic cooling unit valve group for FI cooling, see SW-164.