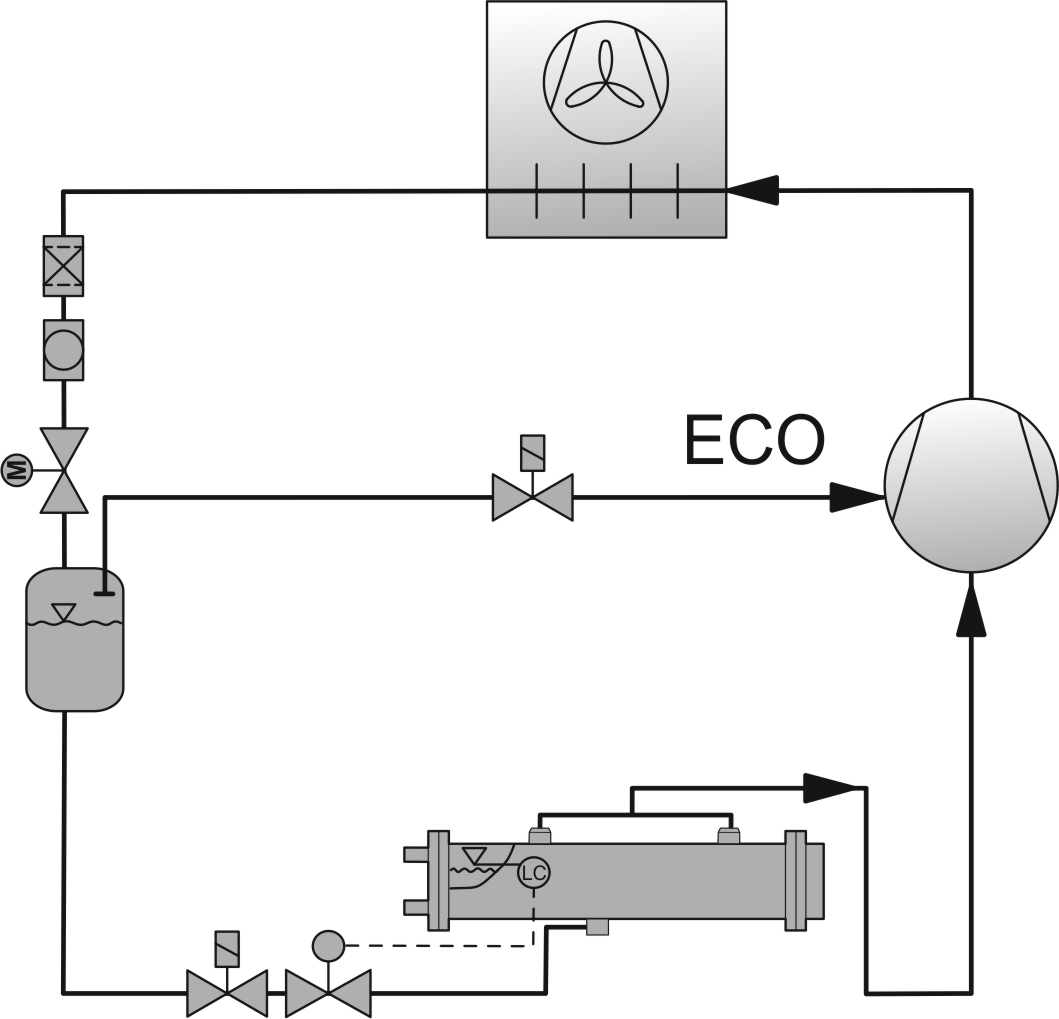

ECO operation with intermediate pressure vessel for two-stage refrigerant expansion

In this system design, an intermediate pressure vessel is arranged between condenser and evaporator. The intermediate pressure vessel should preferably be arranged below the compressor, in order to avoid the return of oil or liquid refrigerant to the compressor during standstill periods.

However, owing to the intermediate pressure being reduced to the saturation temperature, its application is only recommended in connection with flooded evaporators.

- Liquid and gaseous refrigerant (flash gas) are separated in the vessel.

- Liquid refrigerant is relaxed to the intermediate pressure and the flash gas from the intermediate pressure vessel is passed to the ECO channel of the compressor.

- To activate or deactivate ECO operation of the compressor and avoid refrigerant migrations when the system is at standstill, a solenoid valve must be installed in the ECO suction gas line.

Further information, including the selection of the intermediate pressure vessel in the Bitzer Software: Intermediate pressure vessel

Risk of large concentration shifts in the flooded evaporator, and as a result also in the circulating refrigerant mass flow.

Only use refrigerant blends without a significant temperature glide (azeotropic refrigerants) in systems with flooded evaporator!