Oils for HFC and HFO refrigerants

Characterising the oils

Oil | Oil type | Applications | Designation on compressor |

|---|---|---|---|

BSE170 | polyolester oil (POE) | standard oil charge for e.g. CSH.5, CSVH | "Y" (e.g. CSH8593‑140Y) |

BSE170L | polyolester oil (POE) | standard oil charge for e.g. CSH.6, CSW, CSVW | "Y" (e.g. CSVW37-240Y) |

BSE55 | polyolester oil (POE) | standard oil charge for e.g. CSW with motor 4 | "Y" (e.g. CSW8573-80Y) |

B-CE500 | complex ester | standard oil charge for high temperature heat pumps (compressors CSH and CSH2T) with refrigerant R1233zd(E), | "Y" (e.g. CSH2T9573-210Y) |

The approved refrigerants can be found in the respective operating instructions or the Bitzer Software.

Initial charge only with original oils

Risk of compressor damage!

BITZER polyolester oils are mandatory for the running-in period of the compressor. Use only these oils for the initial charge!

BITZER polyolester oils are characterised by specific tribological characteristics and have special wear protection additives which increase the service life of the compressor. The use of alternative oils whose characteristics correspond largely to the original charge is only possible at the system owner’s own responsibility. It is possible to mix them with the original oil, within the respective viscosity group, as long as appropriate own or comparable experience is available for the application concerned. Generally, mixing different oil types may have a negative effect on the properties of the oils. Precondition for the use of alternative oils is that the manufacturer or supplier guarantees product quality and moisture content < 50 ppm.

BITZER will only use BITZER polyolester oils for the complex tests of compatibility with new materials and refrigerants. In case of material changes on products, only BITZER polyolester oils will be included in the tests.

Low GWP refrigerants: stricter requirements for refrigeration systems

Many refrigerant blends with low global warming potential (GWP) such as R448A, R449A, R450A, R452A and R513A contain the unsaturated compounds R1234yf and R1234ze(E). Part of them are highly soluble in oil and lead to a strong reduction of viscosity. Therefore, sufficient superheat has to be ensured! The low chemical stability (which is desirable for a low GWP) requires particular care regarding cleanliness, dryness and evacuation of the refrigerant circuit.

Material safety data sheets

Apart from this document, please observe the material safety data sheet (MSDS) for the respective oil. It contains information on toxicity, handling, personal protective equipment and disposal of the oil. Material safety data sheets for all Bitzer oils are available on request.

Technical data

Oil | Type | Flash-point (°C) | Pour point (°C) | Density (g/ml) | Kinematic viscosity (cSt) | Specific heat capacity (kJ/kg*K) | Thermal conductivity (W/m*K) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

at -30°C | at 15°C | at 100°C | at 20°C | at 40°C | at 100°C | at 40°C | at 100°C | at 40°C | at 100°C | ||||

BSE170 | POE | 260 | -27 | 1.002 | 0.970 | 0.915 | 649 | 170 | 18 | 1.92 | 2.03 | 0.13 | 0.13 |

BSE170L | POE | 246 | -39 | 0.998 | 0.966 | 0.915 | 305 | 97 | 11 | 1.92 | 2.06 | 0.14 | 0.13 |

BSE55/ BSE60K | POE | 280 | -51 | 1.045 | 1.010 | 0.948 | 147 | 55 | 9 | 1.92 | 2.09 | 0.15 | 0.14 |

B-CE500 | complex ester | 221 | -33 | 0.983 | 0.950 | 0.898 | 1611 | 500 | 51 | 2.11 | 2.35 | 0.17 | 0.16 |

Miscibility gaps BSE170

M: Range of complete miscibility.

P: Phase separation range (miscibility gap).

Miscibility gaps BSE170L

M: Range of complete miscibility.

P: Phase separation range (miscibility gap).

Miscibility gaps BSE55

M: Range of complete miscibility.

P: Phase separation range (miscibility gap).

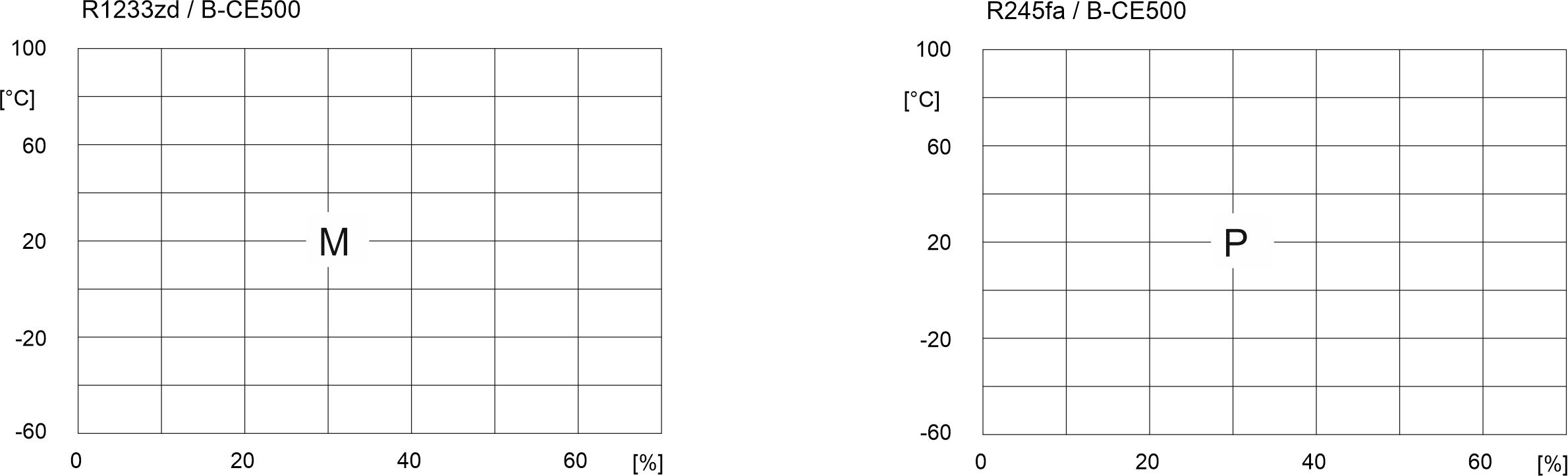

Miscibility gaps B-CE500

M: Range of complete miscibility.

P: Phase separation range (miscibility gap).

Refrigerant solubility in BSE170 and BSE170L

The following diagrams can be used to read off the refrigerant content in the lubricant depending on refrigerant pressure and oil temperature.

Refrigerant solubility in BSE55

Refrigerant solubility in B-CE500

Warning values for used oils

The listed oils are categorized as group KD according to DIN51503-1. To determine the used condition of the oil, e.g. with respect to water content or total acid number (TAN), the reference values of DIN 51503-2, apply.

Oil | Kinematic viscosity at 40°C (DIN EN ISO3104) | Max. water content | Total acid number |

|---|---|---|---|

BSE170 | outside of 145 .. 195 cSt (*) | 200 mg H2O/kg oil | 0.2 mg KOH/g |

BSE170L | outside of 82 .. 112 cSt (*) | 200 mg H2O/kg oil | 0.2 mg KOH/g |

BSE55 | outside of 47 .. 63 cSt (*) | 200 mg H2O/kg oil | 0.2 mg KOH/g |

B-CE500 | outside of 425 .. 575 cSt (*) | 200 mg H2O/kg oil | 0.2 mg KOH/g |

When using A2L refrigerants:

Fire hazard!

The used oil contains a relatively large amount of dissolved refrigerant.

Pack used oil safely. Dispose of in an environmentally friendly manner.

- Hydrocarbons, for example propane, R290 or propene, R1270 and low-fluorinated flammable refrigerants, for example R1234yf, dissolve very well in refrigeration compressor oil at room temperature. This also applies to blends containing these substances.

- Used oil from such systems may still contain relatively high percentages of dissolved flammable gases even at atmospheric pressure. These components gas out.

- Observe during storage and transport:

- Fill used oil into pressure resistant vessels.

- Fill vessels with nitrogen as a protective gas and close them.

- Mark them, e. g. with the warning sign "flammable substance" W021 from ISO7010.

Elastomer compatibility

Relevant literature recommends the following seaI materials for polyolester oils (POE) with HFC and HFO refrigerants:

- acrylonitrile butadiene rubber, nitrile content >36%

- hydrogenated acrylonitrile butadiene rubber, nitrile content >36%

- ethylene propylene diene rubber