ECO operation at part load

Depending on the kind of capacity control and ECO connection, ECO operation is also possible at part load. The following table provides an overview.

Compressor | Kind of mechanical capacity control | ECO connection | ECO feasible with mechanically controlled part load ? | ECO feasible with speed-controlled part load (FI)? |

|---|---|---|---|---|

HS.53 .. 74 | stepped CR by control pistons | fixed in the housing | yes, at capacity step 75% | yes |

HS.85 | dual (stepless or stepped) CR by CR slider | integrated in CR slider | yes | yes |

HS.95 | stepless CR by double slider (CR+Vi) | fixed in the housing | yes, at capacity ≥80% and after consulting Bitzer | yes |

OS.53 .. 74 | stepped CR by control pistons | fixed in the housing | yes, at capacity step 75% | yes |

OS.85 | dual (stepless or stepped) CR by CR slider | integrated in CR slider | yes | yes |

OS.A95 .. 105 | stepless CR by double slider (CR+Vi) | fixed in the housing | yes, at capacity ≥80% and after consulting Bitzer (see below!) | yes (see below!) |

CSH65 .. 95 | dual (stepless or stepped) CR by CR slider | integrated in CR slider | yes | yes |

CSH76 .. 96 | dual (stepless or stepped) CR by CR slider | fixed in the housing | no | yes |

CSW65 .. 95 | dual (stepless or stepped) CR by CR slider | fixed in the housing | no | yes |

CSW105 | stepless CR by double slider (CR+Vi) | fixed in the housing | yes, at capacity ≥80% and after consulting Bitzer | yes |

CSV | -- | fixed in the housing | -- (only FI operation) | yes |

VSK | stepped CR by control pistons | -- | -- | yes |

OS.A95 and OS.A105: Pulsation muffler during economiser operation

For OS.A95 and OS.A105 compressors in ECO operation, a pulsation muffler in the economiser line is recommended resp. necessary. Two options are available:

- a muffler system, consisting of muffler, check valve, control valve (one unit is required for OS.A95, two units are required for OS.A105)

- a basic pulsation muffler designated SD42 (part no. ePARTS: 354 004 05)

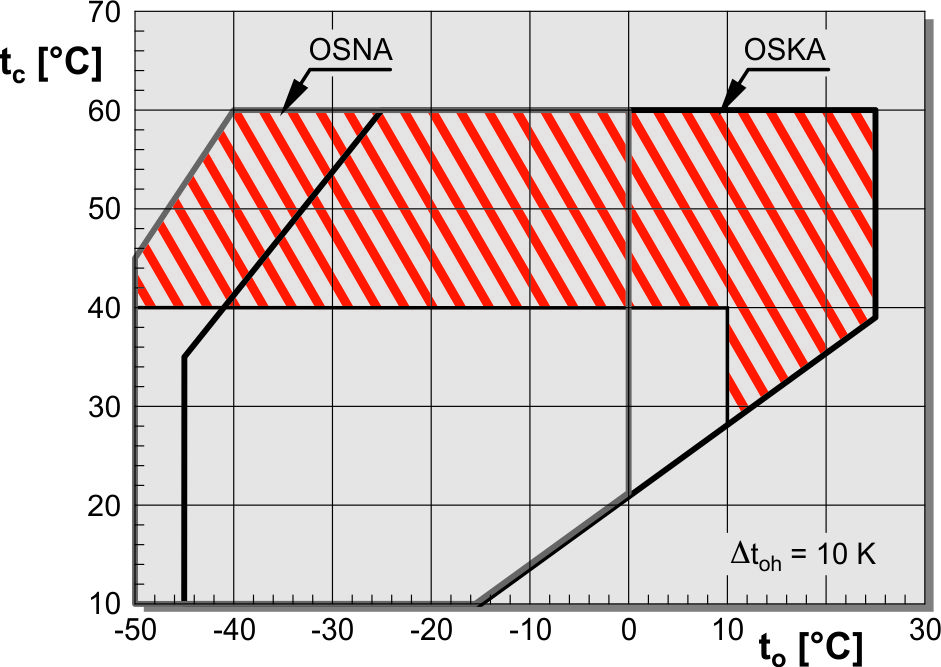

For operation at condensing temperatures > 40°C and/or evaporation temperatures > 10°C, the muffler system is mandatory. In the remaining range, BITZER recommends the pulsation muffler SD42. For details see the following figure and table.

Planned operating range | Pulsation muffler | Possible scope of capacity regulation |

|---|---|---|

Operation in the shaded area of the application limit (tc > 40°C and/or to > 10°C) | Economiser muffler system is mandatory |

|

Operation outside the shaded area of the application limit (tc < 40°C and to < 10°C) | Optional: economiser muffler system |

|

Optional: basic pulsation muffler SD42 in ECO connection |

|

See also: