Recommended start and stop sequences

DANGER

DANGER

Life-threatening voltages inside the frequency inverter housing!

Contact can lead to serious injuries or death.

Never open the FI housing in operation! Switch off the main switch and secure it against being switched on again.

Wait for at least 10 minutes until all capacitors have been discharged!

Before switching on again, close the FI housing.

CAUTION

CAUTION

In operation, the heat sink of the frequency inverter will get hot.

Risk of burns upon contact!

Prior to performing work on the frequency inverter, disconnect the power supply and wait for at least 15 minutes until the heat sink has cooled down.

Risk of compressor failure!

Operate the compressor only in the intended rotation direction!

The following diagrams show some examples for start and stop sequences. They enable a soft start, but also a sufficient oil supply for the compressor.

During operation, frequency changes should be much slower than during start and stop (Configuration of the frequency inverter).

Apart from the exceptions explained below:

Compressor and motor damage!

Do not combine a frequency inverter with mechanical capacity control of the compressor! Especially at low speed, adequate motor cooling is not guaranteed because refrigerant mass flow is heavily reduced. Certain exceptions for screw compressors are possible in consultation with Bitzer.

If the compressor is operated with the CM-SW-01 module and frequency inverter mode, the module controls the mechanical capacity sliders and the oil solenoid valve.

Compressors CS.65 .. 95

Start sequence:

For special operating conditions at high evaporation and condensing temperatures the frequency inverter may be combined with CR 75%. In the following diagram showing application limits, this is the white area at the bottom right (for application limits, see also above):

Stop sequence:

Compressors CS.105 and HS.95 with CM-SW-01 module

The combination of frequency inverter and slider capacity regulation is not authorised for CS. and HS. compressors with CM-SW-01. After compressor start, the sliders automatically move to full load position, after compressor stop they are not actively unloaded. This enables a faster new start because the capacity control by frequency inverter can start directly – without increased risk of the compressor not reaching its operating limits in time.

Compressors HS.53 .. 74 and OS.53 .. 74

Start sequence:

Stop sequence:

Compressors HS.85 and OS.85 (without CM-SW-01 module)

Start sequence:

Stop sequence:

Compressors OS.A85 .. 105 with CM-SW-01 module

While the integrated motor of the semi-hermetic CS. and HS. compressors provide enough reserve for pull down conditions, this isn't necessarily the case for the OS. compressors: Here, the motor can be selected for the specific application, e.g. a relatively small one might be used for low temperature applications. As a result, it may be necessary to reduce the load by slider control until nominal operating conditions are reached, in order to not overload the motor. Since the motor cooling with very low refrigerant mass flow is not such an important issue for open drive compressors as it is for CS. and HS. compressors, slider capacity control can be combined with frequency inverter control for pull down conditions. In this case, the minimum slider capacity position is limited to 50%.

Start sequence:

Stop sequence:

Start / Stop sequences with economiser operation

In principle, the above sequences apply also to economiser operation, but observe the altered application limits (see Bitzer Software)! The economiser may be started as soon as operating conditions are stable, and is shut off together with the frequency inverter.

OS.A95 and OS.A105: Pulsation muffler during economiser operation

For OS.A95 and OS.A105 compressors in ECO operation, a pulsation muffler in the economiser line is recommended resp. necessary. Two options are available:

- a muffler system, consisting of muffler, check valve, control valve (one unit is required for OS.A95, two units are required for OS.A105)

- a basic pulsation muffler designated SD42 (part no. ePARTS: 354 004 05)

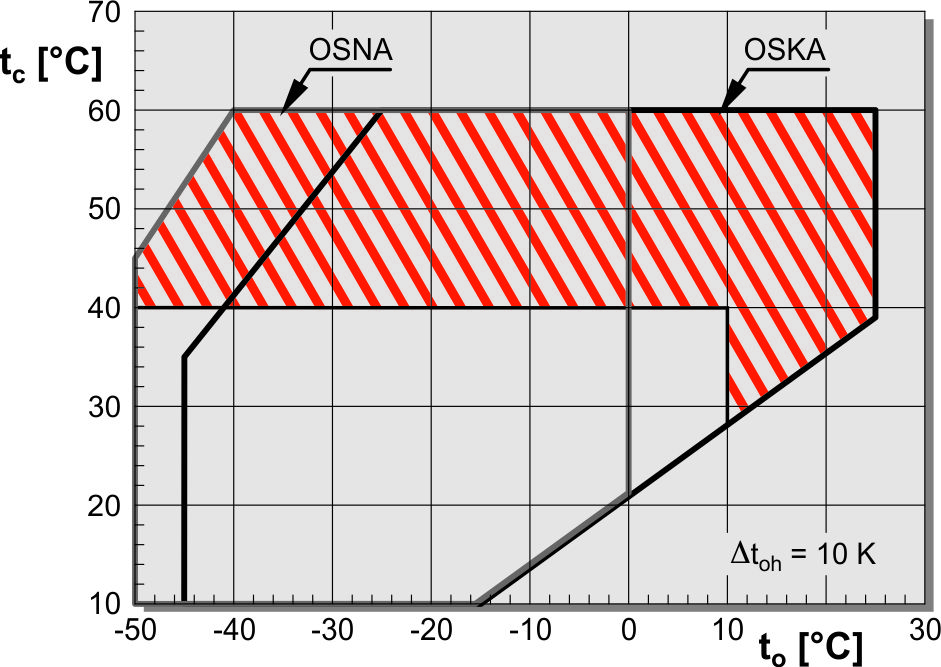

For operation at condensing temperatures > 40°C and/or evaporation temperatures > 10°C, the muffler system is mandatory. In the remaining range, BITZER recommends the pulsation muffler SD42. For details see the following figure and table.

Planned operating range | Pulsation muffler | Possible scope of capacity regulation |

|---|---|---|

Operation in the shaded area of the application limit (tc > 40°C and/or to > 10°C) | Economiser muffler system is mandatory |

|

Operation outside the shaded area of the application limit (tc < 40°C and to < 10°C) | Optional: economiser muffler system |

|

Optional: basic pulsation muffler SD42 in ECO connection |

|

See also:

- ST-430: Capacity control of BITZER screw compressors

- ST-610: Economiser operation of screw compressors

Start and stop in compound systems

- If one compressor is operated with frequency inverter: Start the compressor as described above, then switch on the compressor without frequency inverter as usual when needed. For stop, first shut off the compressor without frequency inverter, then stop the compressor with frequency inverter as described above.

- Compound system with frequency inverter on each compressor: Use the start and stop sequences as described above. The compressors start one after the other, depending on the control of the compound.