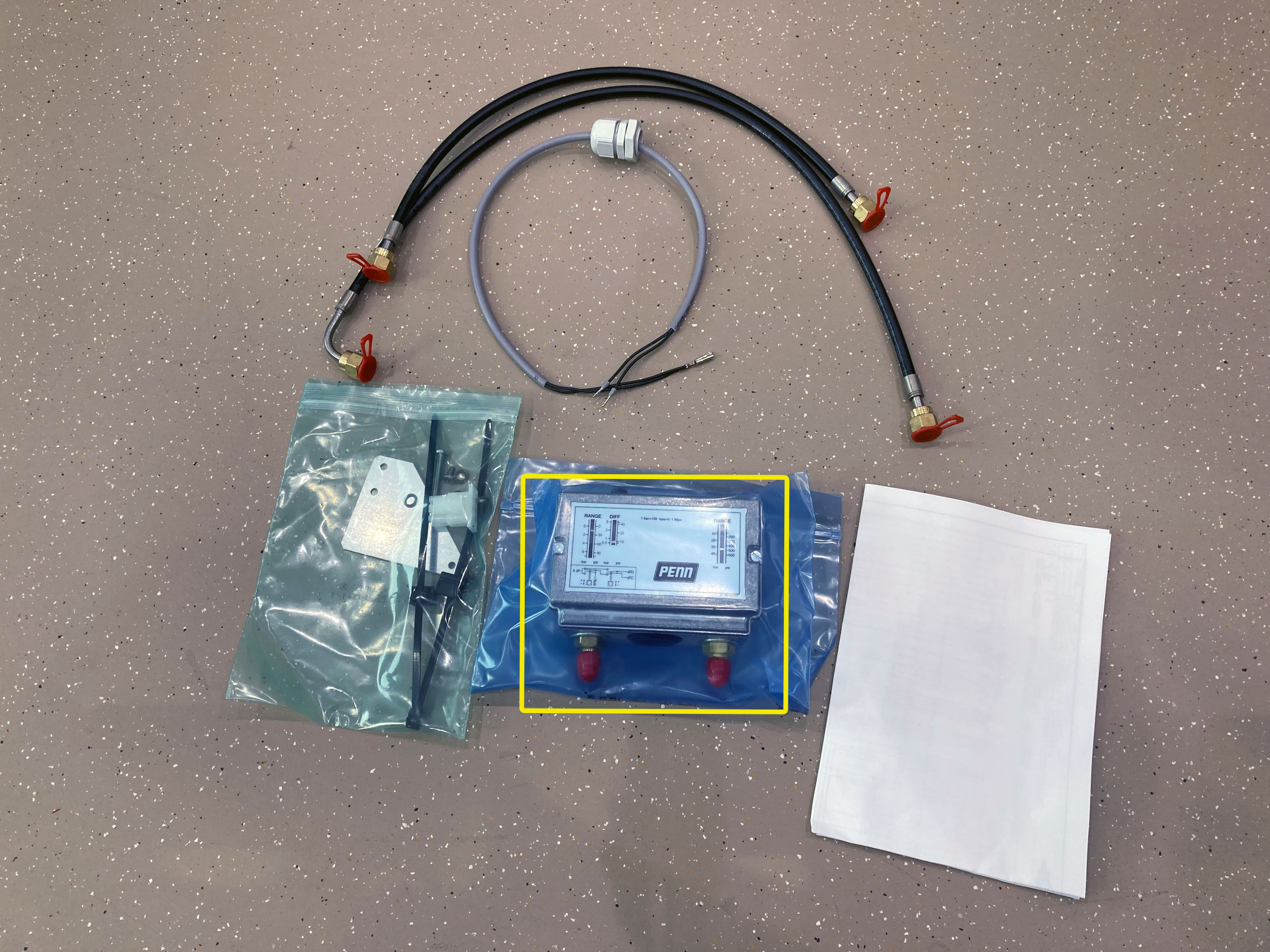

Install new adjustable pressure switch

Connect cable (2) of new adjustable pressure switch to new plug X4

Connect oil heater cables (brown and blue) to new plug

Attach new plug X4 to terminal strip

The following 3 steps have to be done only if the terminal box is not already prepared.

Measure hole spacing at mounting plate

- Scale

Plot drill holes on terminal box

- Pencil

- Scale

Drill holes into terminal box

- Drilling machine with 4.5 mm drill bit

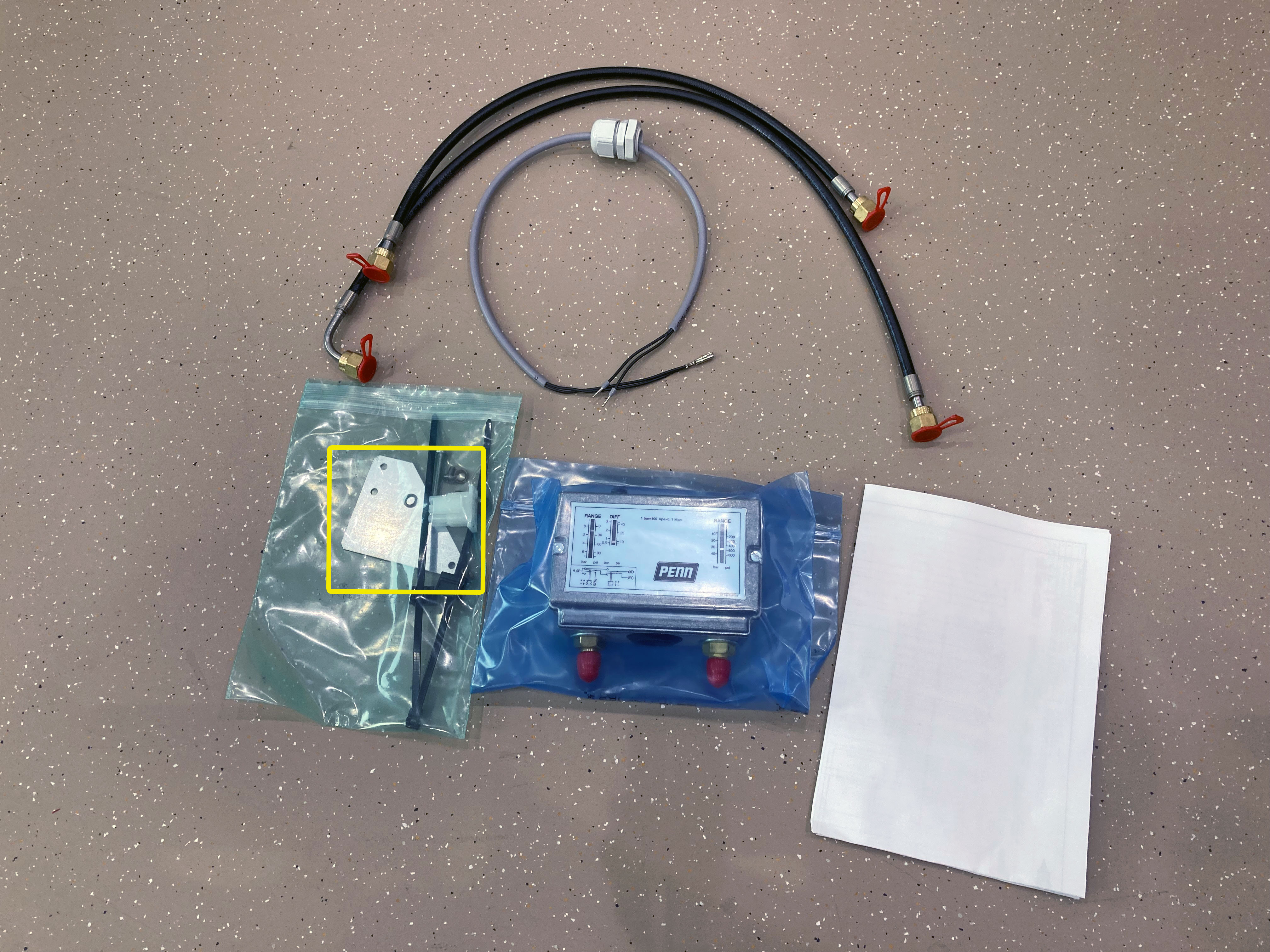

Attach mounting plate to new adjustable pressure switch by using the included screws

Preset cut-out pressures of the new, adjustable pressure switch

High pressure:

- cut-out pressure: 32 bar

- cut-in pressure difference: 4 bar

Low pressure:

- cut-out pressure: -0,3 bar

- cut-in pressure difference: 0,7 bar

- Phillips screwdriver

Remove cover of new adjustable pressure switch

- Phillips screwdriver

Penetrate through-hole in pressure switch

- Phillips screwdriver

Attach new ajustable pressure switch with mounting plate to terminal box

- Phillips screwdriver

- Included screws

Attach new pressure switch with mounting plate to terminal box

- Phlillips screwdriver

- Two M4 nuts (if the terminal box is not already prepared)

Install cable of new low and high pressure switch, attach screwed cable gland

Connect cable (2) to pressure switch

- Phillips screwdriver

Connect cable (1) to pressure switch and close black cover

- Needle nose pliers

- Phillips screwdriver

Attach cover of new adjustable pressure switch

- Phillips screwdriver

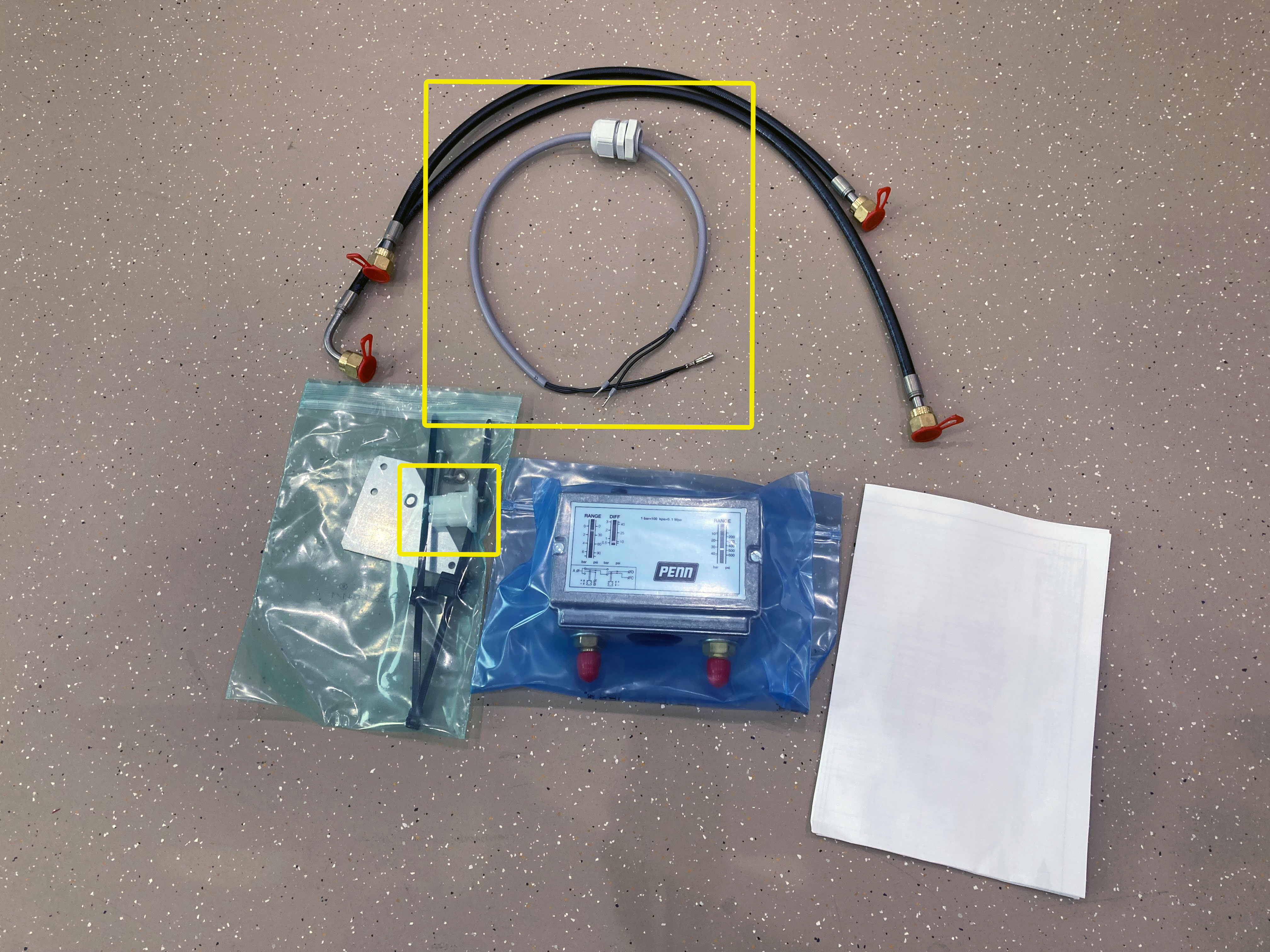

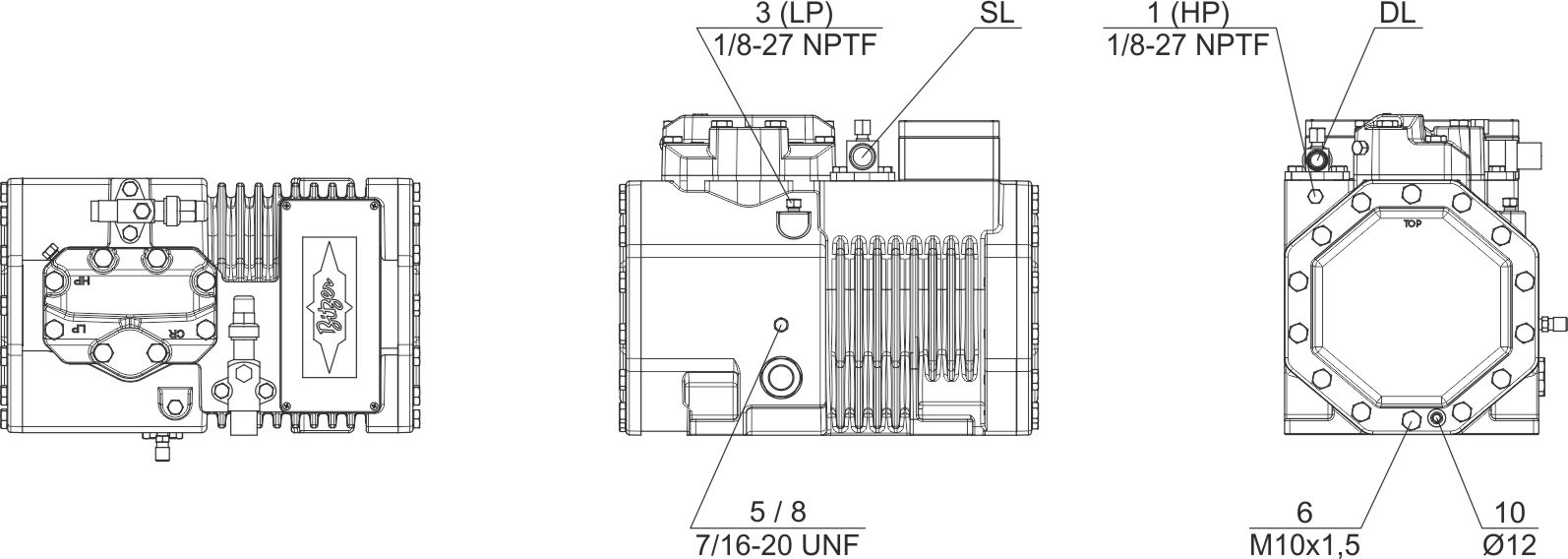

Attach capillary hose with copper gasket to low pressure switch connection of compressor

LHL3E

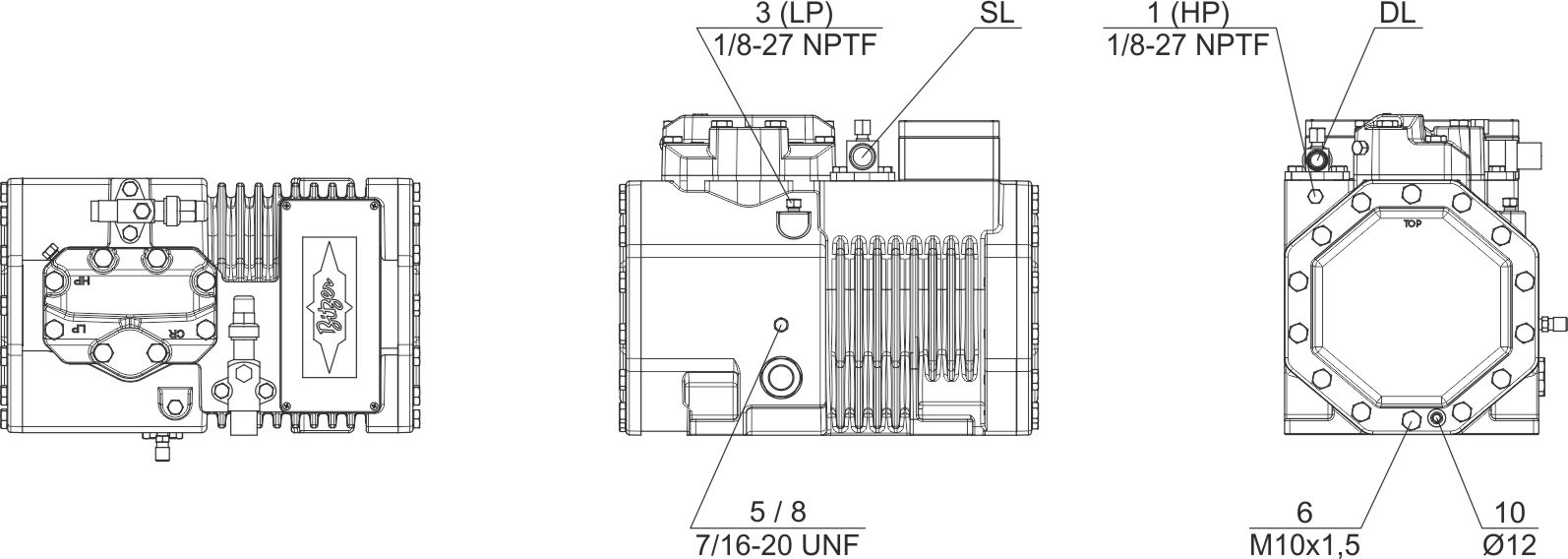

The LHL3E condensing units contain 2 cylinder compressors (2EES .. 2CES) instead of 4 cylinder compressors as shown in the video. The positions of the low and high pressure switches differ:

1 (HP) | Connection for high pressure switch (HP) | 3 (LP) | Connection for low pressure switch (LP) |

Attach capillary hose with copper gasket to high pressure switch connection of compressor

LHL3E

The LHL3E condensing units contain 2 cylinder compressors (2EES .. 2CES) instead of 4 cylinder compressors as shown in the video. The positions of the low and high pressure switches differ:

1 (HP) | Connection for high pressure switch (HP) | 3 (LP) | Connection for low pressure switch (LP) |

Mount capillary hoses to compressor

- High pressure switch connection: Spanners SW 16 and SW 13 to counter-hold

- Low pressure switch connection: Spaners SW 16 and SW 12 (or open-ended spanner) to counter-hold

- Open-ended spanner

Mount capillary hoses to new pressure switch

- Spanners SW 16 and SW 17 to counter-hold

Attach cable ties

- Cable ties

Close cable duct

Attach lateral housing plate

- 4 mm hexagon spanner