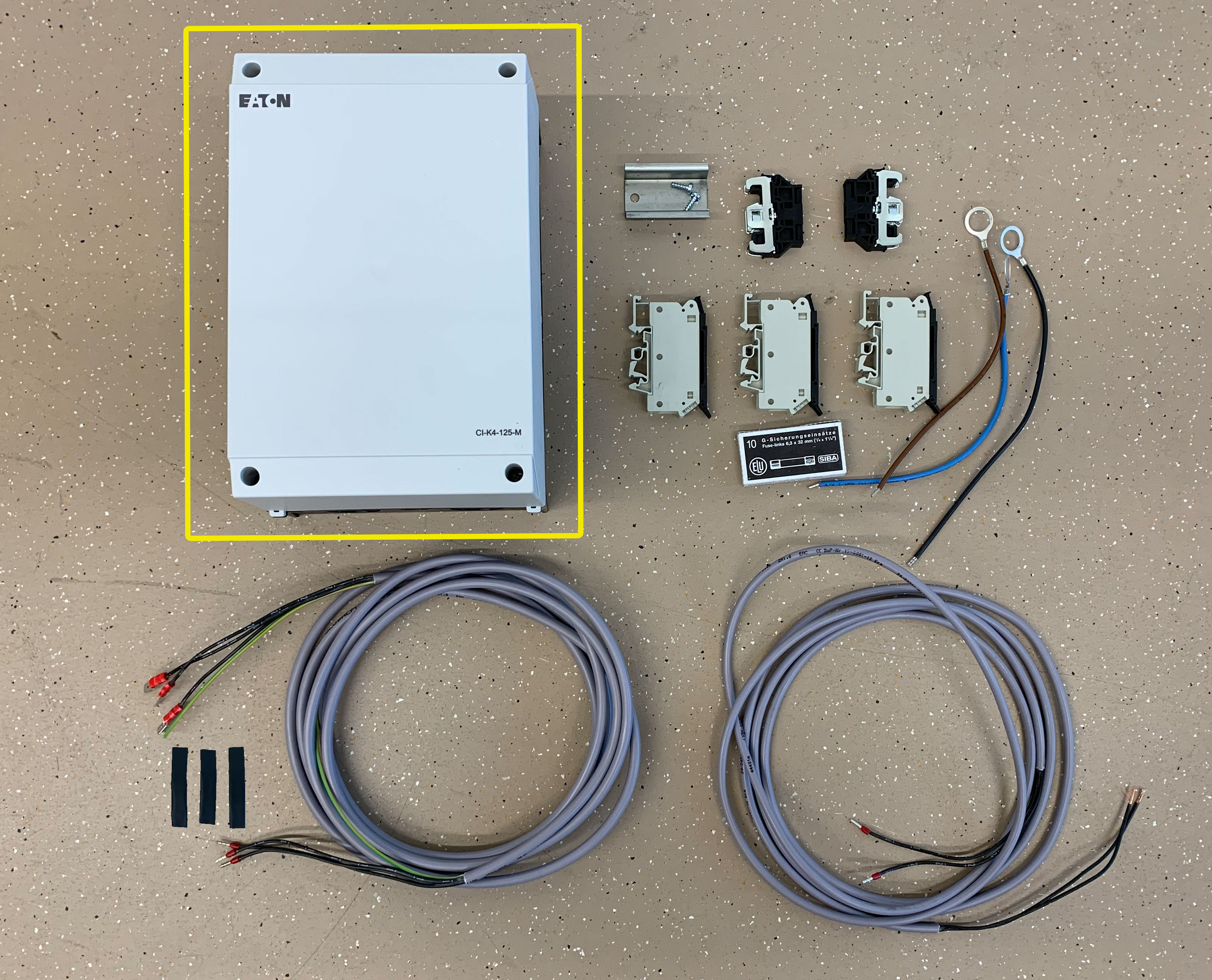

Outside the terminal box for A3 regrigerants

If the SE-i1 is used with refrigerants classified as A3 (e.g. propane) and A2, it must not be installed inside the terminal box of the compressor

It must be installed outside the terminal box of the compressor, either in an external terminal box (at least IP54), or inside the system's switch cabinet.

Authorized staff

All work done on the products and the systems in which they are or will be installed may only be performed by qualified and authorised staff who have been trained and instructed in all work. The qualification and competence of the qualified staff must correspond to the local regulations and guidelines.

Connect the 3 cable cores (black, brown, blue) of phase monitoring to fuse terminals

- Screwdriver

- After mounting, check electrical cable connections for tightness!

Connect cable cores of PTC resistors for monitoring the motor winding temperature to terminals 5 and 6

- Screwdriver

- After mounting, check electrical cable connections for tightness!

Open cable bushing at terminal box

- Screwdriver handle

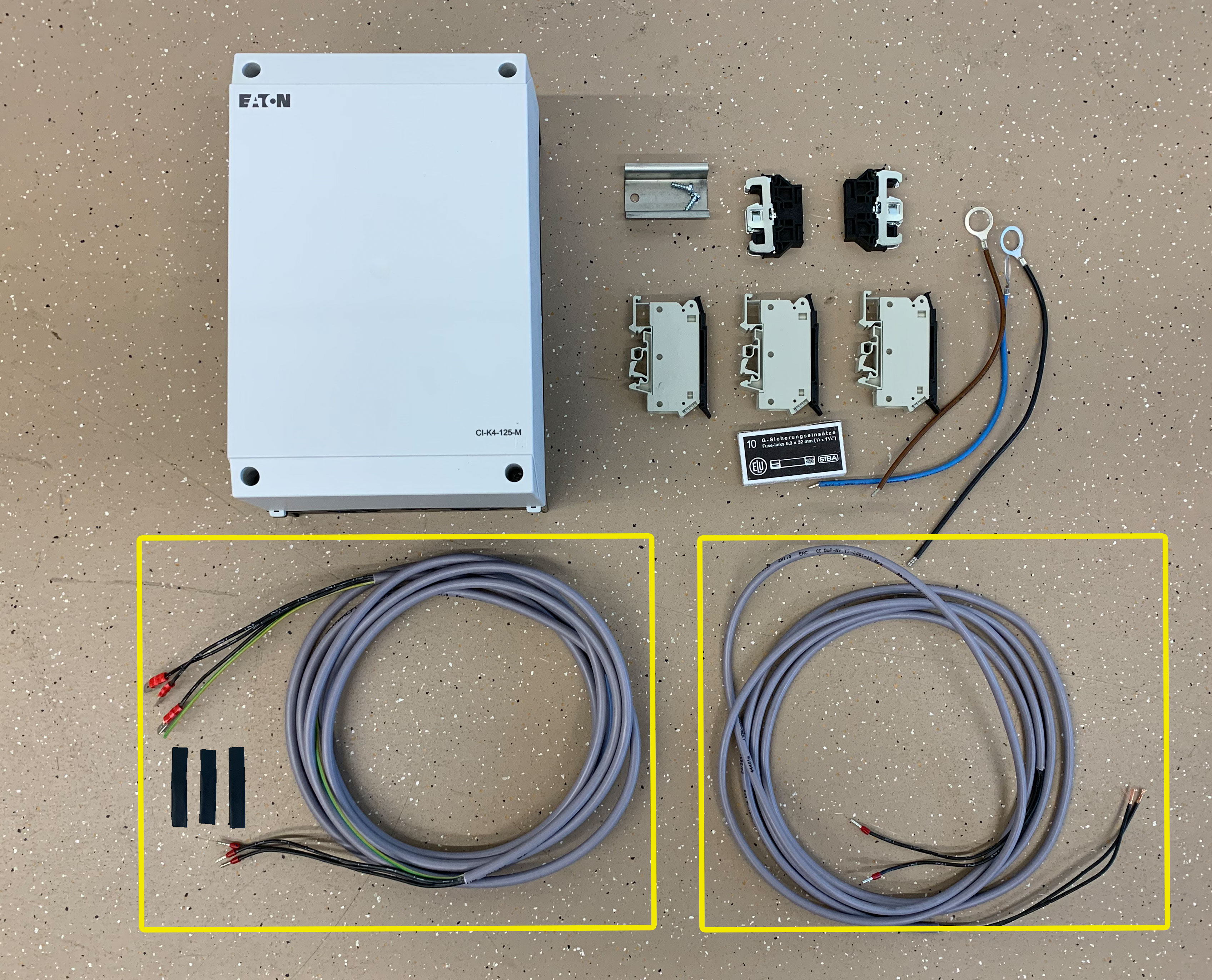

Guide connecting cable of "Motor PTC" and "Phase monitoring" into terminal box

Maximum admissible cable length for PTC temperature control circuit tested according to UL/EN60335: 10 m

Maximum admissible cable length for PTC temperature control circuit tested according to EN12693: 30 m

Maximum admissible cable length for PTC temperature control circuit tested according to UL/EN60335: 10 m

Cable lengths > 30 m are not tested during type approval!

Connect cable cores of connecting cable of "Phase monitoring" to fuse terminals in terminal box

- Screwdriver

- Cable 1→ black

- Cable 2 → brown

- Cable 3 → blue

- After mounting, check electrical cable connections for tightness!

Connect cable cores of connecting cable of "Motor PTC" to terminals 5 and 6

- Screwdriver

- After mounting, check electrical cable connections for tightness!

Attach terminal box cover

- 5 mm hexagon spanner

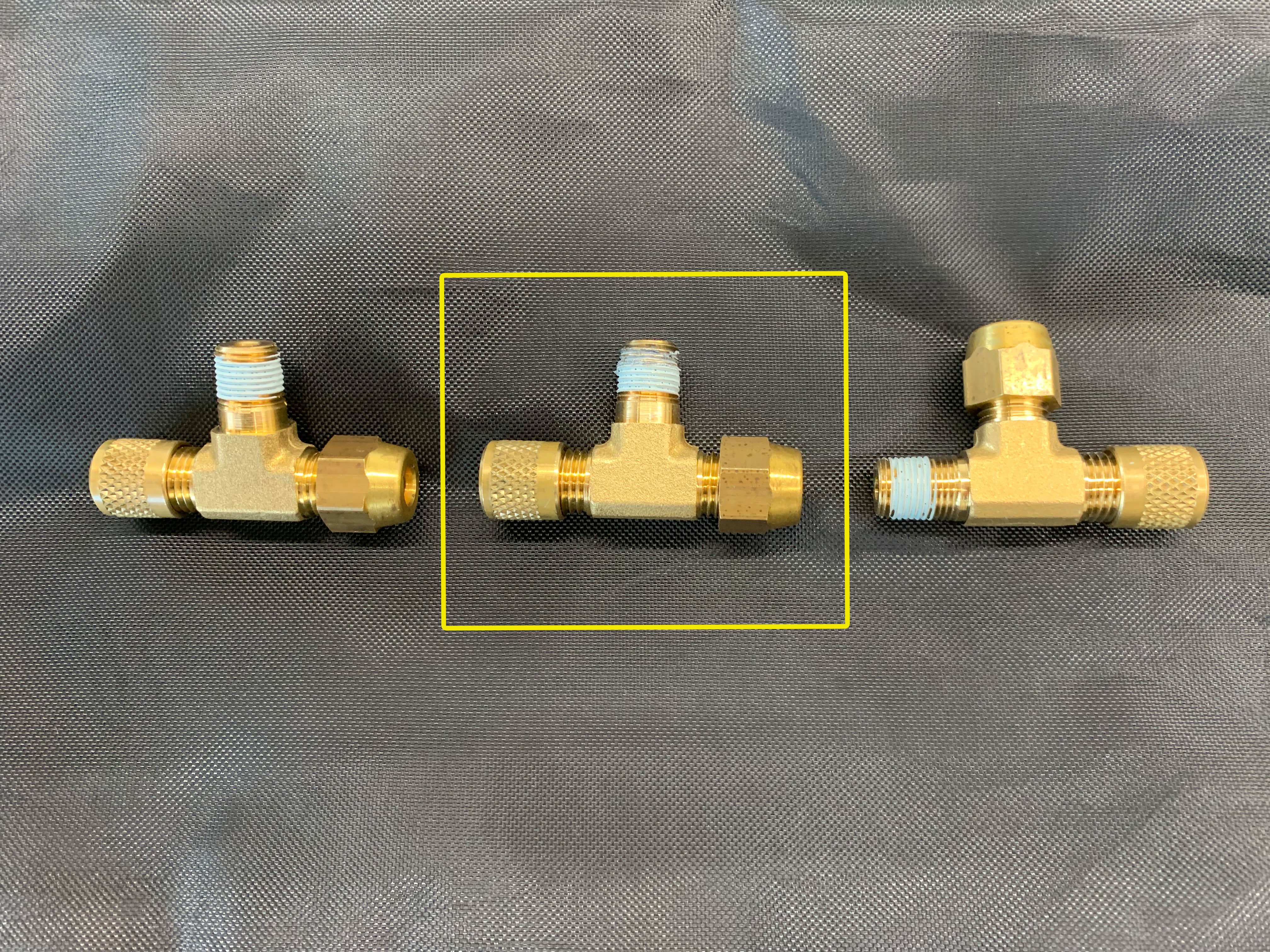

Attach T joint for mounting the high pressure transmitter

- Ring wrench / spanner SW 13

- Spanner SW 14

The connection positions for pressure transmitters at the CS. series vary depending on compressor size. The following videos show the positions for a CS.85 compressor.

Attach T joint for mounting the low pressure transmitter

- Ring wrench / spanner SW 13

- Spanner SW 14

The connection positions for pressure transmitters at the CS. series vary depending on compressor size. The following videos show the positions for a CS.85 compressor.

Mount the low pressure transmitter

- Spanner SW 16 (counter-hold with spanner SW 14)

- Suitable refrigeration compressor oil

- Torque spanner

- Tightening torque: 35 Nm

Mount the high pressure transmitter

- Spanner SW 16 (counter-hold with spanner SW 14)

- Suitable refrigeration compressor oil

- Torque spanner

- Tightening torque: 35 Nm

Create a vacuum at the high pressure side (at least -0,5 bar)

This ensures that no oil leaks through the connection when the discharge gas temperature sensor gets replaced.

- Vacuum pump

Remove existing discharge gas temperature sensor (PTC) and install new discharge gas temperature sensor (NTC)

- Work quickly!

- Ratchet wrench with socket spanner size 17

Mount new discharge gas temperature sensor (NTC)

- Ratchet wrench with socket spanner size 17

- Torque spanner

- Tightening torque: 17 Nm

Switch off and remove vacuum pump

Detach cover of external terminal box

Alternative installation in the system's switch cabinet!

- Phillips scewdriver

Drill holes (for M4x10 screws) into the assembly panel of the external terminal box to attach the SE-i1

- Drill

- See dimensional drawing for details

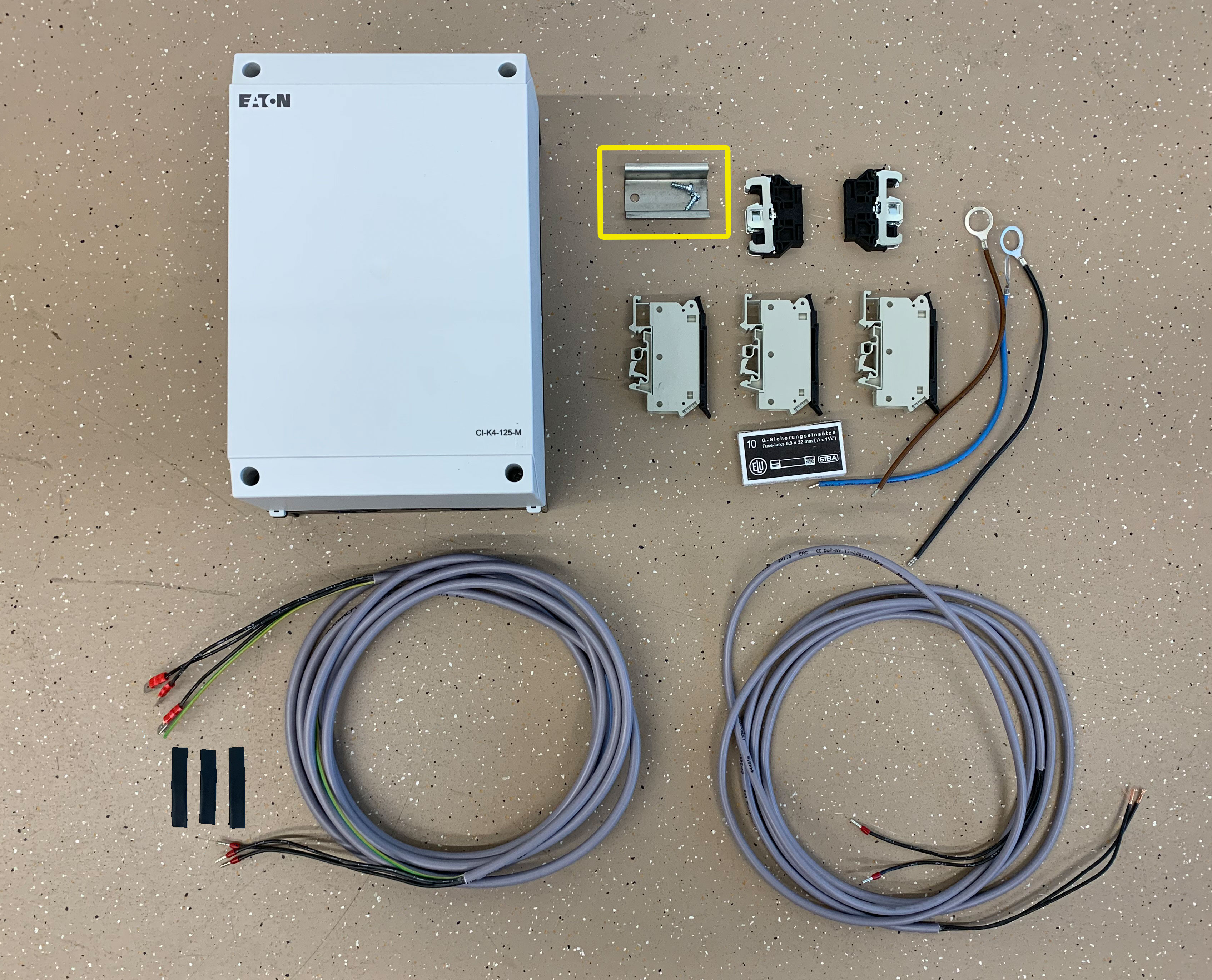

Attach SE-i1 with washers, screws (M4x10) and nuts to assembly panel

- Hexagon spanner 5 mm

- Pliers

Open cable bushings at external terminal box

- Screwdriver

Attach suitable screwed cable glands to external terminal box

Mount SE-i1 with assembly panel into external terminal box

- Phillips screwdriver

Guide cable of discharge gas temperature sensor (NTC) into external terminal box

Guide cable of low pressure transmitter into external terminal box

Guide cable of high pressure transmitter into external terminal box

Connect cable cores of discharge temperature sensor (NTC) to terminals 12 and 13 of SE-i1

- Screwdriver

- Brown cable → terminal 12

- White cable → terminal 13

- After mounting, check electrical cable connections for tightness!

Connect cable cores of high pressure transmitter to terminals 14, 15, 16 of SE-i1

- Screwdriver

- Cable 1 → Terminal 14

- Cable 3 → Terminal 15

- Cable 2→ Terminal 16

- After mounting, check electrical cable connections for tightness!

Connect cable cores of low pressure transmitter to terminals 17, 18, 19 of SE-i1

- Screwdriver

- Cable 1 → Terminal 17

- Cable 3 → Terminal 18

- Cable 2 → Terminal 19

- After mounting, check electrical cable connections for tightness!

Guide connecting cable of "Motor PTC" and "Phase monitoring" into external terminal box

Connect cable cores of PTC resistors for monitoring the motor winding temperature to terminals 8 and 9

- Screwdriver

- After mounting, check electrical cable connections for tightness!

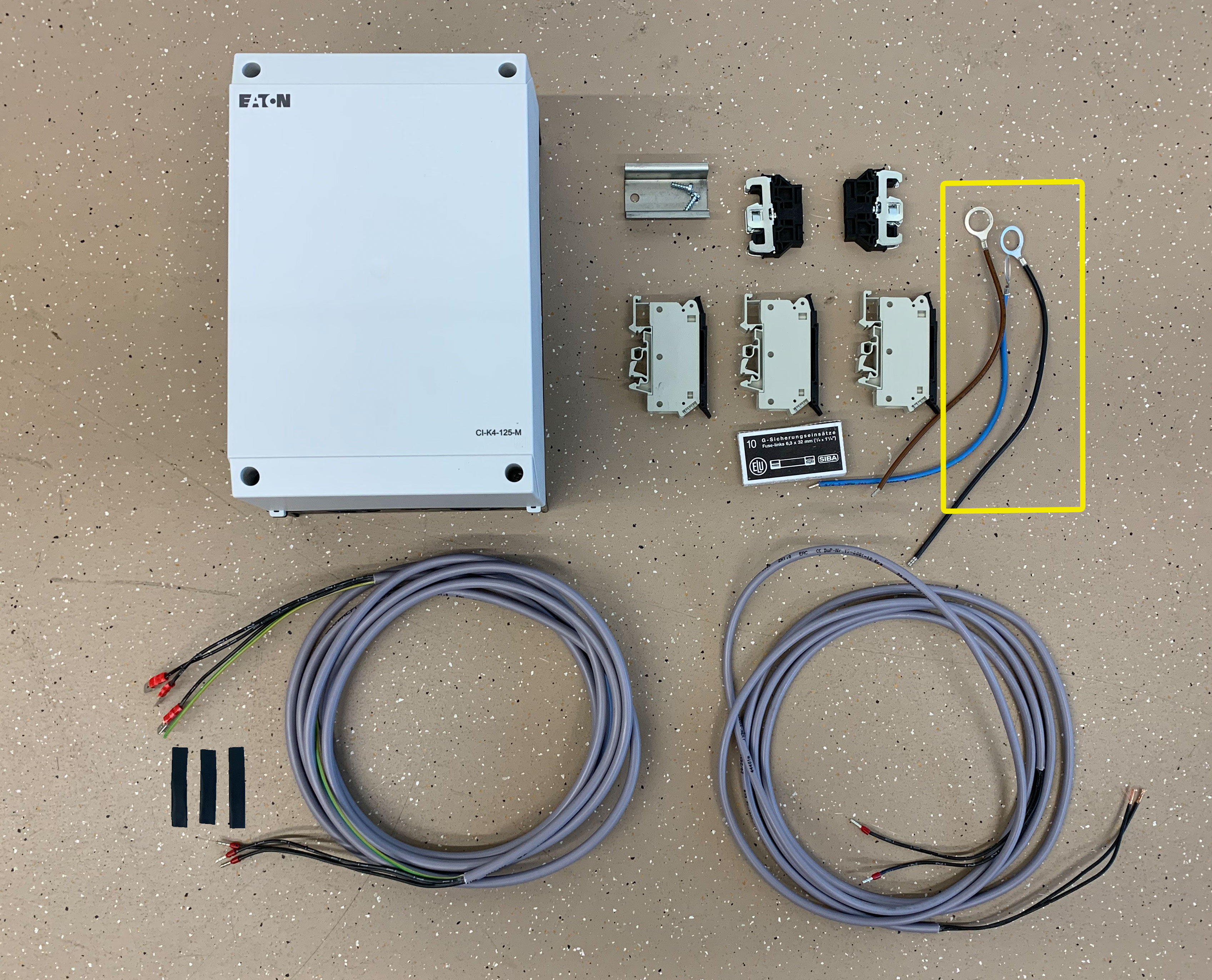

Attach cable lugs of Phase monitoring and position shrinking tubes

- Cable 1 → black

- Cable 2 → brown

- Cable 3 → blue

- After mounting, check electrical cable connections for tightness!

Shrink shrinking tubes

Place cables carefully in external terminal box

Configure all BEST SOFTWARE settings and then:

Attach cover of external terminal box

- Phillips screwdriver