Ejector in high lift applications

Ejectors in high lift applications are used to achieve the highest possible pressure lift at a lower delivery rate. The pressure lift and the suction mass flow to be delivered are the limiting factors and must be balanced in the system such that the highest possible efficiency is achieved.

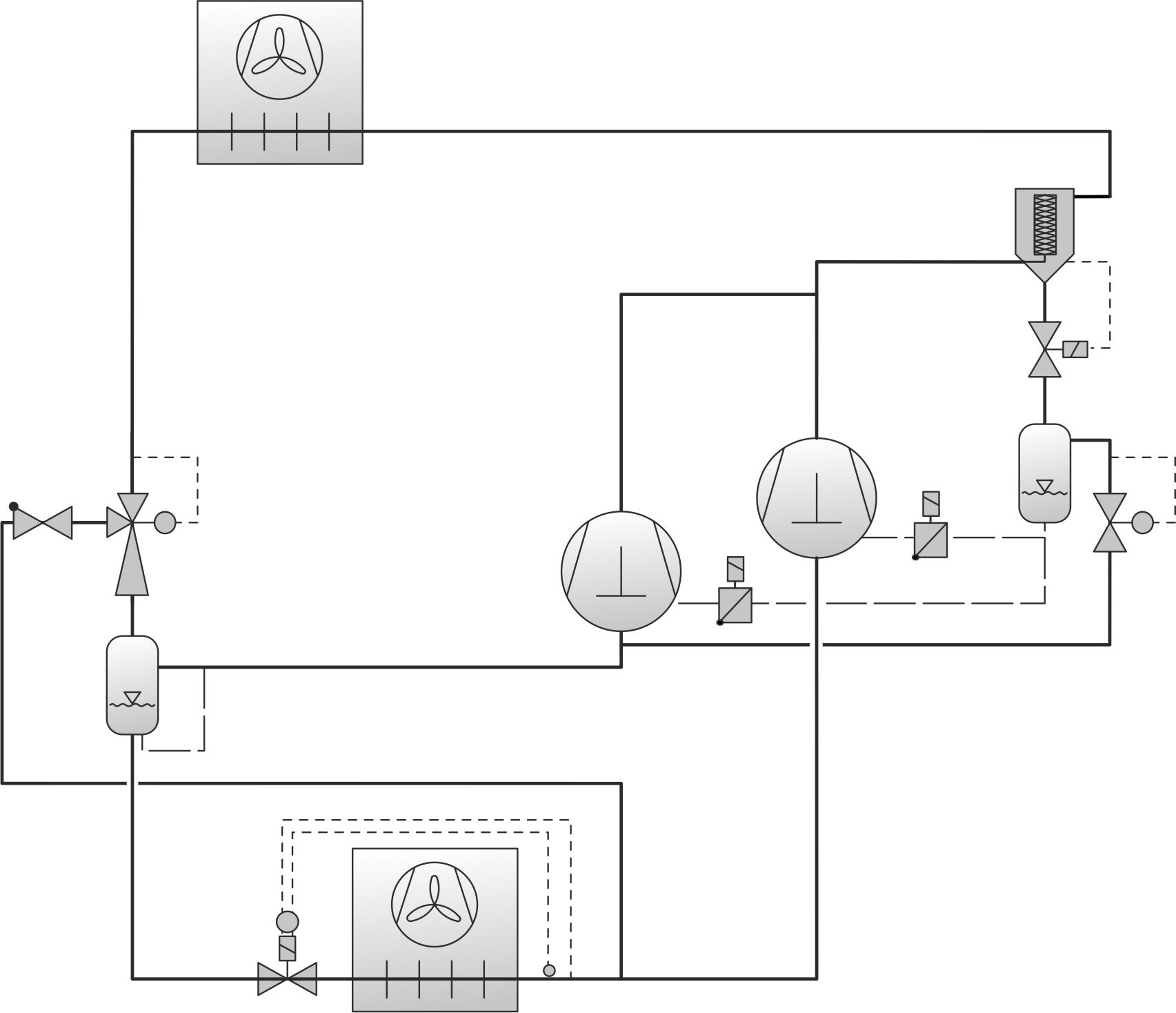

Ejectors in high lift applications are usually used to transport superheated gas, as they do not transport the entire mass flow from the evaporator and a partial mass flow must continue to be extracted by the medium temperature compressors. The partial mass flow transported by the ejector is returned to the intermediate pressure vessel of the system which is kept here at a higher pressure level than in a low lift version. The gas is extracted there by the parallel compressors.

The advantage lies here in the pre-compression of part of the evaporated refrigerant and the resulting load shift to the parallel compressors which operate at a lower pressure ratio and thus more efficiently.

Design example of a high lift ejector created with the help of BITZER SOFTWARE see here.