Application with Bitzer screw compressors

Bitzer screw compressors are equipped with capacity control by means of control sliders or control pistons. This allows (stepped, stepless or dual) capacity control as well as automatic start unloading through appropriate control of the solenoid valves. For start unloading, the capacity control is set to minimum displacement, ideally before the compressor is switched off. If this is not possible, enough time must be provided before the compressor is restarted, e.g. for the control slider to move to the appropriate position (pause time). For detailed information, see the respective Operating Instructions.

With direct-on-line, star-delta and part winding start, complete unloading of the screw compressor is essential to enable a reliable start and to avoid increased starting currents or a shutdown of the compressor!

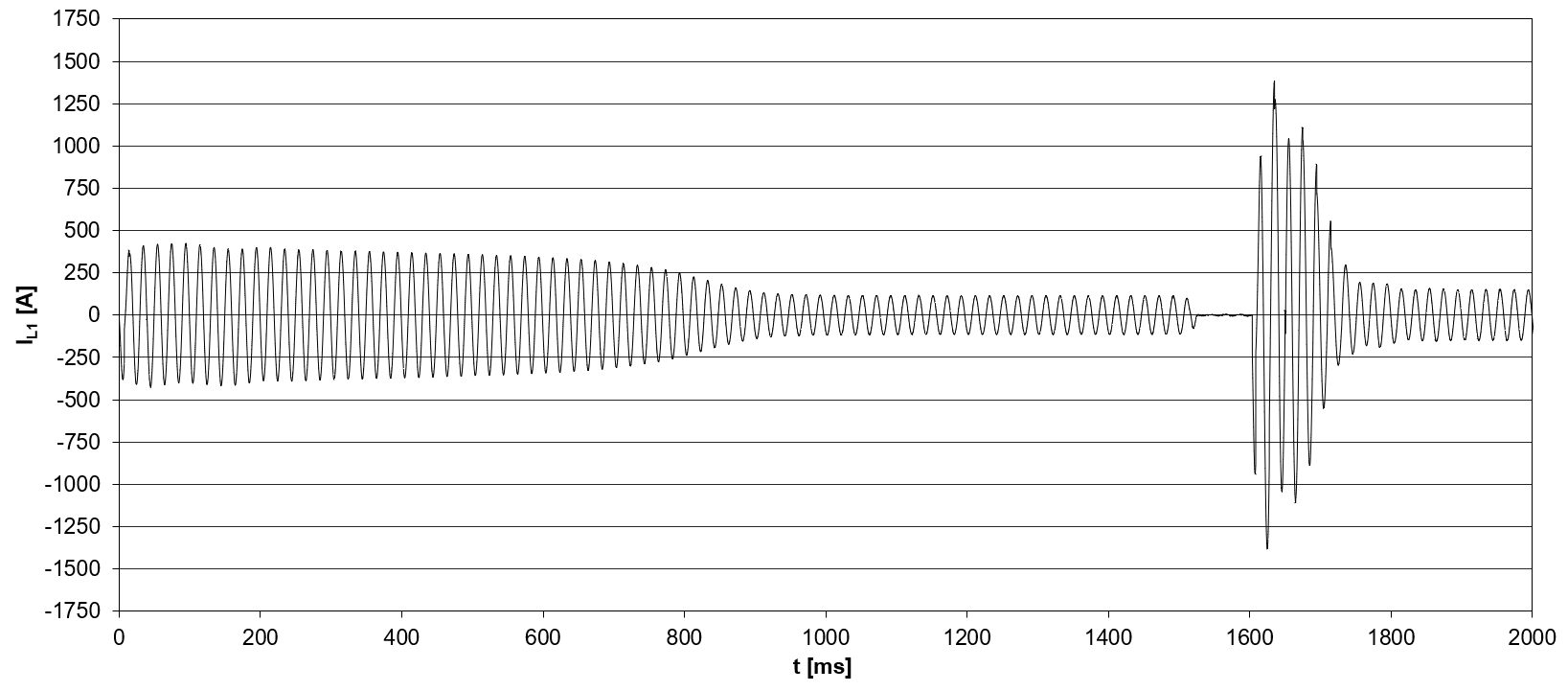

Comparison of starting currents

As an example, the starting currents for a typical CS. compressor are shown. The starting current indicated in the Bitzer Software is the root mean square (RMS) value of the current. To derive this from the oscillogram, the current must be divided by √2.

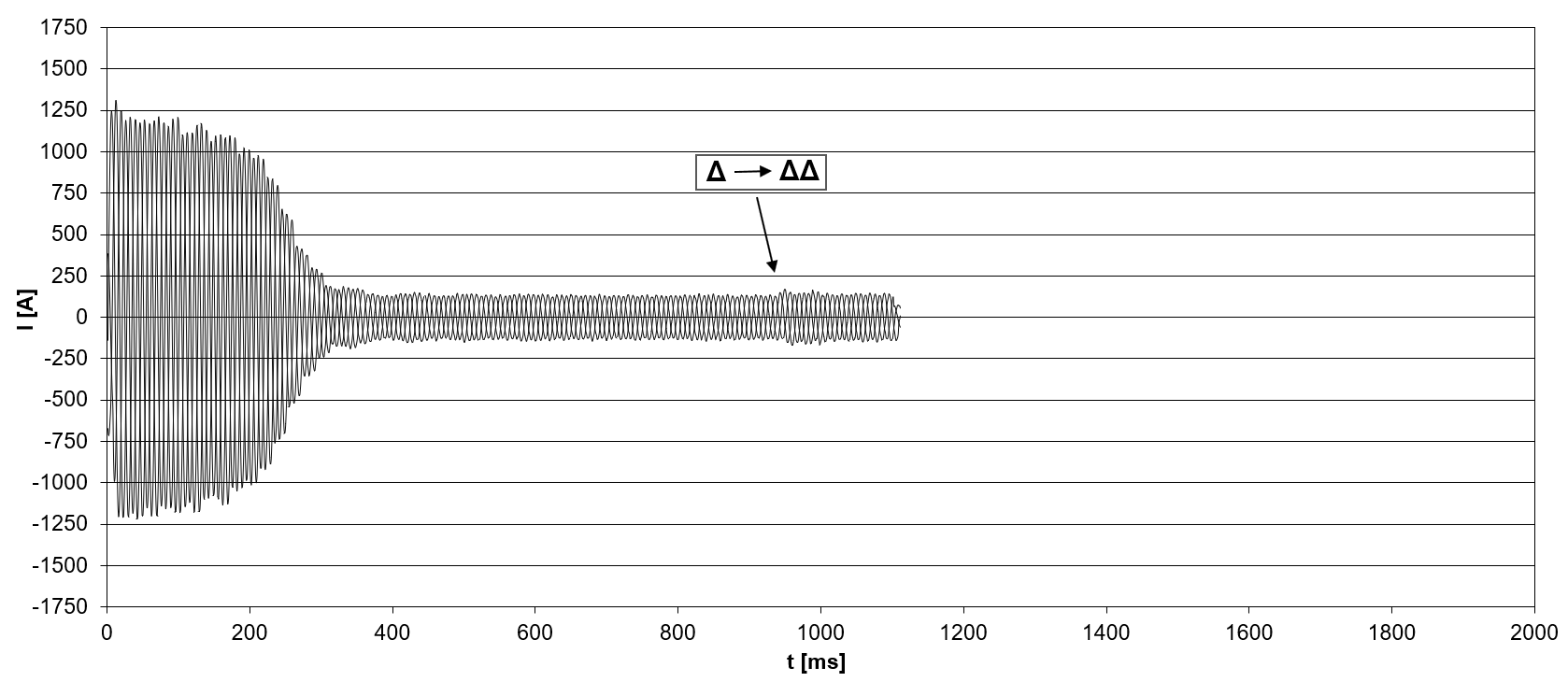

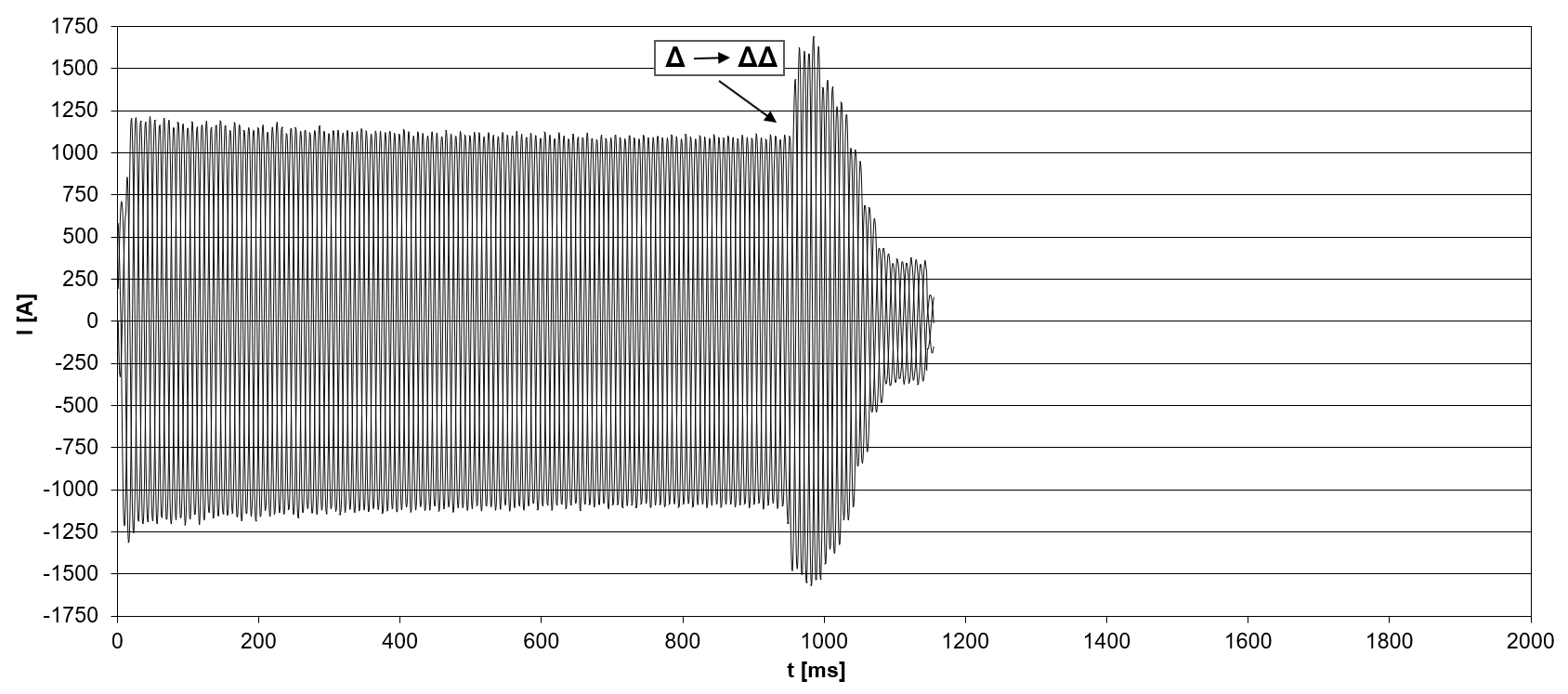

Part winding start with slider at 25% vs. 100%:

The compressor does not start until the 2. part winding is switched on, because only then the torque is sufficient.

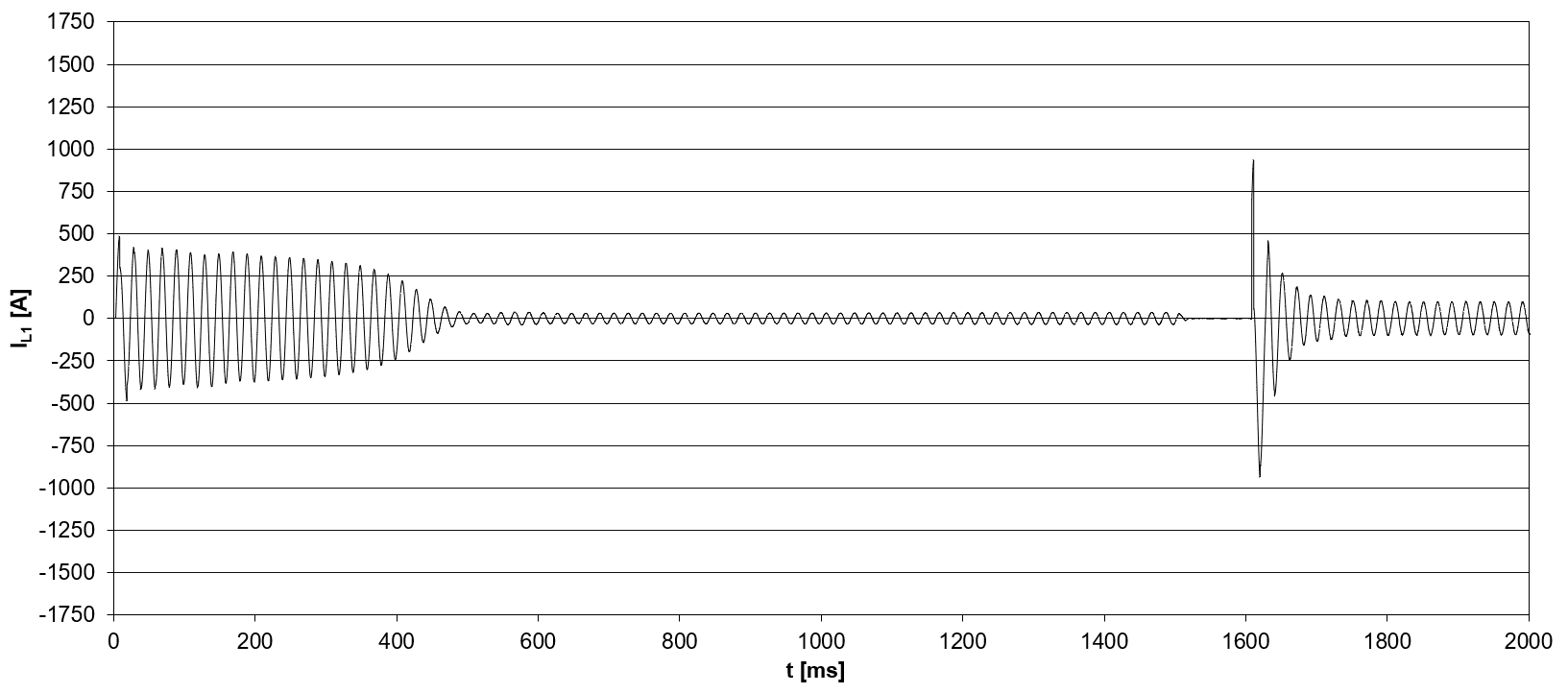

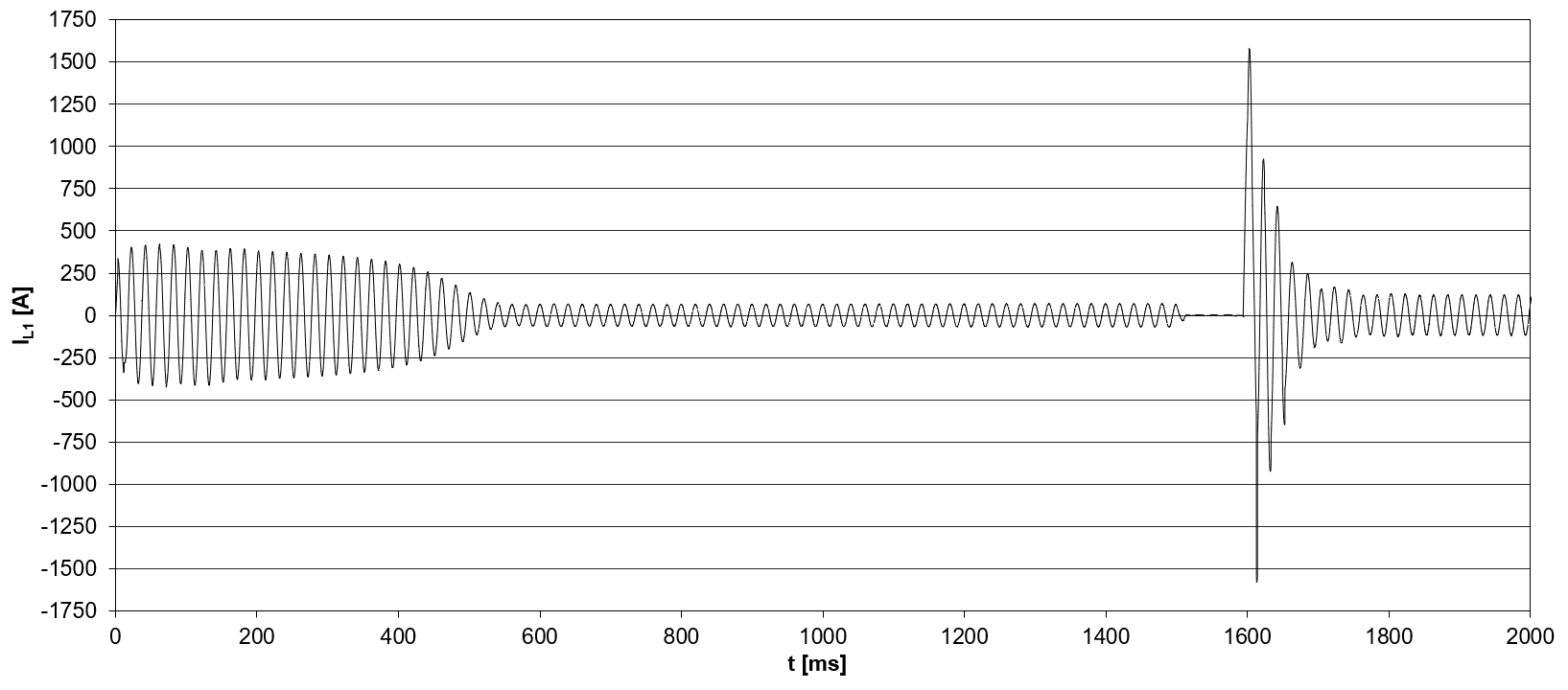

Star-delta start with slider at 25%, 50%, 75%:

Information on measuring the real starting current: Application with BITZER compressors.

Information in the Bitzer Software

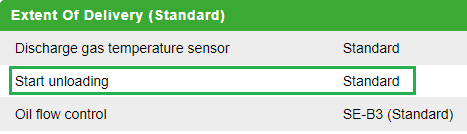

If a specific compressor is selected in the Bitzer Software, start unloading is listed in the tab "Technical Data":

Schematic wiring diagram

In screw compressors, start unloading is carried out via the capacity control, therefore it is not explicitly listed in the schematic wiring diagram.