Fresh variety, sustainably cooled – fruit wholesaler relies on propane

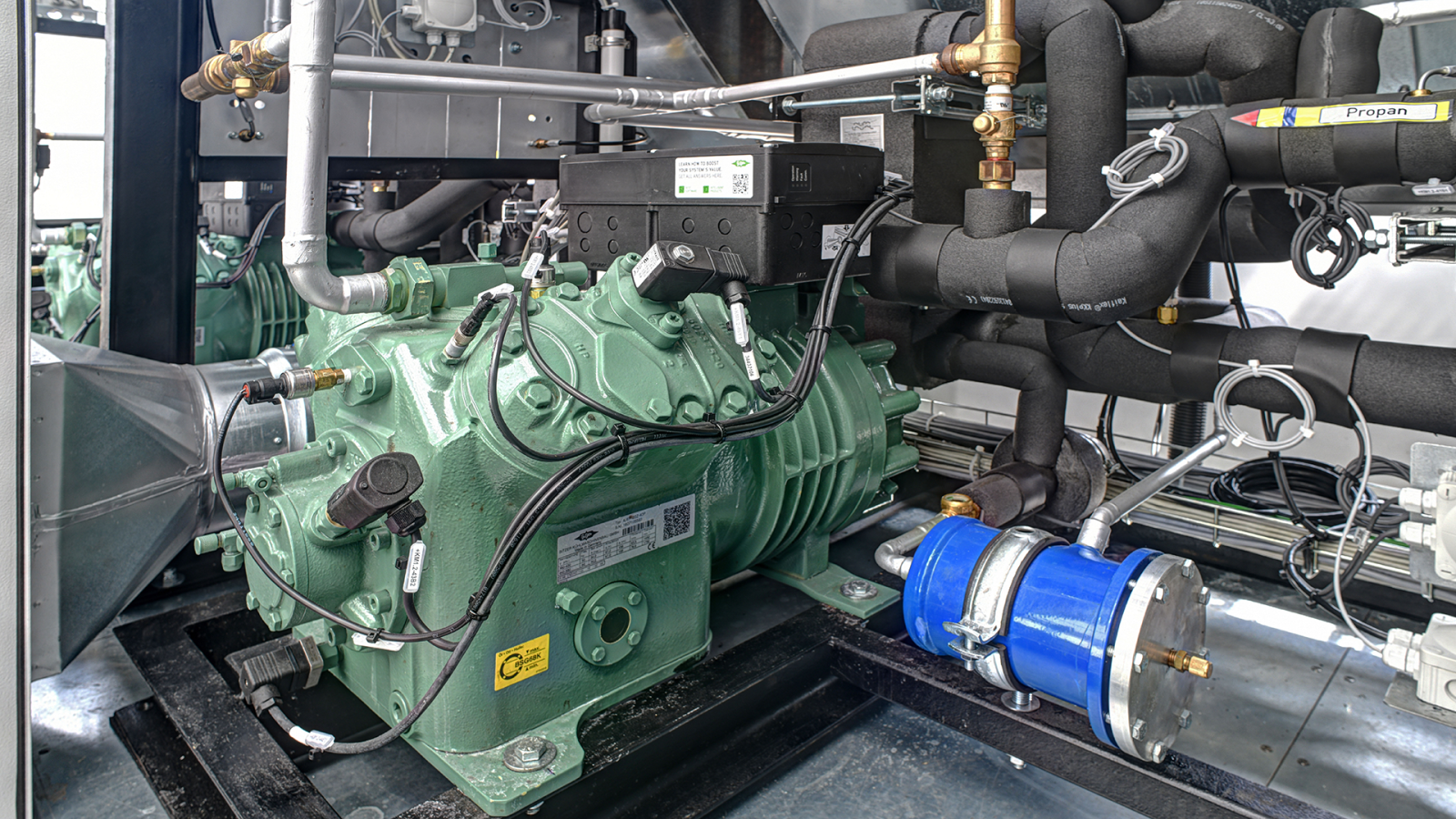

Every day, Fruchthof Northeim supplies culinary establishments, communal caterers, food retailers and other bulk consumers with fresh fruit and vegetables. A new FrigoNatura® propane liquid chiller from Frigotec GmbH ensures optimal storage conditions in cold stores. Two highly efficient 4-cylinder reciprocating compressors from the BITZER ECOLINE PRO series fitted with the IQ MODULE CM-RC-02 form the heart of the system.

To ensure long-term planning reliability, reduce energy and operating costs, and improve its overall carbon footprint, Fruchthof Northeim decided to convert its existing R404A refrigeration system to a future-proof alternative. With its high global warming potential (GWP = 3922), the R404A refrigerant used previously is affected by the accelerated phase-out of HFCs in accordance with EU F-gas Regulation 2024/573. This led to the choice of the natural refrigerant propane (R290). During the first phase of the project, the refrigeration for two cold stores was modernised, and the connections for future construction phases were prepared. For the modernisation work, Fruchthof Northeim placed its trust in Frigotec, its partner of many years specialising in tailored refrigeration solutions for the food industry.

FrigoNatura®: liquid chillers for propane

‘We are thrilled that the first system of our new FrigoNatura® series was successfully commissioned at Fruchthof Northeim in March 2025,’ says Lucas Einenkel, authorised director and member of the management board at Frigotec GmbH. The liquid chillers of the FrigoNatura® series have been optimised for the refrigerant propane and are available in four capacity steps. With its low environmental impact (GWP = 3) and outstanding thermodynamic qualities, propane is considered to be a future-proof refrigerant. In its new FrigoNatura® series, Frigotec is using reciprocating compressors from the BITZER ECOLINE PRO series. These compressors were specially developed for the particular requirements of hydrocarbons and offer efficiency, reliability and a high degree of flexibility when it comes to system design: 26 displacements and refrigerating capacities (propane) of 0.9 to 110 kW at t0 = –10°C, tC = +45°C at 50 Hz are available. Frigotec GmbH develops and manufactures the liquid chillers exclusively at its headquarters in Landsberg, Saxony-Anhalt. Prior to delivery, each system is thoroughly tested and activated to ensure the utmost in quality and safety. DEKRA approval as per the EU Pressure Equipment Directive 2014/68 also takes place at the factory to ensure rapid commissioning at the customer’s premises.

State-of-the-art refrigeration for the storage of fruit and vegetables

The Fruchthof Northeim system supplies a total refrigerating capacity of 61.8 kW (reference values: t0= –10°C/tc= +40°C), divided across two refrigerant circuits. Among other things, this ensures increased operational reliability for the system. The selection of fruit and vegetables, which varies depending on the season, is stored in two cold stores with a total area of 167 m2 and at a constant temperature of +4°C. Sensitive refrigerated good such as mushrooms, carrots, parsley and asparagus thus retain their high quality and leave the warehouse as if freshly harvested. Northeim is one of three Fruchthof locations in central Germany. A total of up to 15000 tonnes of fruit and vegetables are handled daily.

With the dismantling of the existing system being carried out gradually, the space available for the new refrigeration system was extremely limited – meaning that compact dimensions were required. The new propane liquid chiller is an outdoor installation in front of the building. On the cold-brine side, the system is connected to two storage tanks, each with a capacity of 2500 litres. The storage tanks are located in a separate machinery room set up as a container solution right next to the liquid chiller. The medium used is ethylene glycol, which is conveyed to the evaporators in the two Fruchthof cold stores via speed controlled pumps. Connections for additional pumps required in future modernisation work have been prepared in advance. Air cooled condensers have also been used in this project.

Maximum energy efficiency with an eye for detail

The previous refrigeration system of the Fruchthof consumed a large amount of energy, particularly during peak demand in the summer months – offering considerable potential for savings. To allow a sustainable reduction in energy consumption and the associated operating costs, Frigotec focused on selecting energy-efficient system components, as well as optimised control technology. Highlights include the Siemens MLV702 magnetic expansion valve, for example, which contributes to system stability and efficiency thanks to its rapid and precise response time. The liquid chiller also features heat recovery, allowing the waste heat generated by the refrigeration system to be used for heating the building once all cold stores have been modernised.

By using the BITZER ECOLINE PRO 4-cylinder reciprocating compressors at the heart of the propane liquid chiller, Frigotec is placing its trust in a reliable partner: ‘We have been using BITZER components from the very start. The compressors run reliably and we trust the quality behind them. The reciprocating compressors are also manufactured very close to us in Schkeuditz,’ says Lucas Einenkel. BITZER and Frigotec worked together closely throughout the project.

The compressors are fitted with the IQ MODULE CM-RC-02, guaranteeing even more efficient and reliable operation thanks to its intelligent functions. The module’s prewiring at the BITZER factory and intuitive operating concept also simplified installation of the compressors thanks to reduced cabling requirements in the switch cabinet. Construction of the switch cabinet and programming of the master system control (Siemens PLC S7) were also conducted by Frigotec. The IQ MODULE with extension board in the compressor terminal box allows compressor functions to be connected to the PLC in the liquid chiller and controlled directly from the module. The master system control (PLC) also provides remote access to the liquid chiller.

Intelligent functions and state-of-the-art capacity control

Frigotec uses the PREMIUM extension board (CM-IO-B) in all liquid chillers in the FrigoNatura® series. This means that compressors in the new Fruchthof Northeim refrigeration system are equipped with application limit monitoring, a DP-2 differential oil pressure switch, discharge gas sensors, and additional temperature sensors to measure suction gas temperature and monitor wet operation. This guarantees a high level of system availability at all times. VARISTEP mechanical capacity control is also used for efficient part load operation. In the current application case, this facilitates a reduction in refrigerating capacity to 50% of the compressor capacity. In relation to the total refrigerating capacity of the liquid chiller, this results in a reduction of the total capacity to 25%.

Safety with propane

The design of the new Fruchthof refrigeration system meets the highest operational safety standards with the refrigerant propane, which, as a hydrocarbon, is included in safety class A3. Among other features, the system is equipped with a gas warning sensor, an exhaust fan and a warning light with siren. Thanks to the design and testing of their seal systems, the ECOLINE PRO compressors used also offer the advantage of enhanced tightness in accordance with EN1127-1. There is no need to assume an ATEX zone around the compressors, which ensures a high degree of safety and simplifies the necessary system risk assessment.

Sound data for rapid optimisation

Due to the high value of products in the Fruchthof warehouses and the sensitivity of the refrigerated goods, the project requirements also included being able to react promptly in the event of system failures and to support the customer at all times, including remotely. A sound framework of data is therefore essential. The system control, programmed by Frigotec, provides experts with detailed insights into crucial system parameters at all times. Any error messages are forwarded directly via the Frigotec Connect app to ensure that appropriate steps can be taken quickly. In conjunction with the BEST SOFTWARE or app, the IQ MODULE also allows continuous access to compressor operating data to support evaluation, analysis and optimisation. ‘So far, our experience with the IQ MODULE has been excellent. We gain insights into the comprehensive compressor data and see which operating conditions the compressors are running at. By using the IQ MODULE, we also receive detailed compressor data on top of the system data. This allows us to draw conclusions regarding the compressor’s operating behaviour and thus to increase the operational reliability of the system,’ says Lucas Einenkel.

Propane: a refrigerant with a future

The installation of the new Fruchthof Northeim refrigeration system was successfully completed within three weeks with no interruption to active operation. During this time, the goods from the two cold stores that required retrofitting were temporarily stored in a third cold store. The end user was highly satisfied with the way the project progressed. Additional cold rooms will soon be upgraded in the same way to future-proof the site.

‘The project with Fruchthof Northeim proved to be a successful start for our FrigoNatura® series. We look forward to forthcoming projects,’ concludes Lucas Einenkel. For example, the largest design for the new liquid chiller, with a refrigerating capacity of more than 400 kW and four ECOLINE PRO 8-cylinder reciprocating compressors, was commissioned in June 2025 at a jam manufacturer – projects like this demonstrate the potential of propane as a future-proof refrigerant.

Frigotec Homepage