Cutting-edge cooling technology for XXL supermarket distribution centre

To optimise its logistics network, an Italian discount chain has established a new, state-of-the-art distribution centre in northern Italy. With a total area of 182,000 m², of which 112,000 m² are covered, this distribution centre is one of the largest in the region. To ensure that fruits, vegetables, dairy and sausage products retain their freshness and quality in the storage rooms, precise and reliable cooling is essential. FRIGOVENETA has designed and implemented five chillers with highly efficient BITZER CSW105 compact screw compressors, which ensure optimal temperatures in the storage rooms.

The new distribution centre was built within three years and consolidates the previous, smaller distribution centres of the discount chain in northern Italy. Up to 60 million picked packaging units leave the warehouse annually through over 120 loading bays, supplying the entire store network in the northern part of the country. The location of the distribution centre was chosen for its logistical advantages, as it is well connected to the main hubs of northern Italy.

Reliable cooling technology – the be-all and end-all

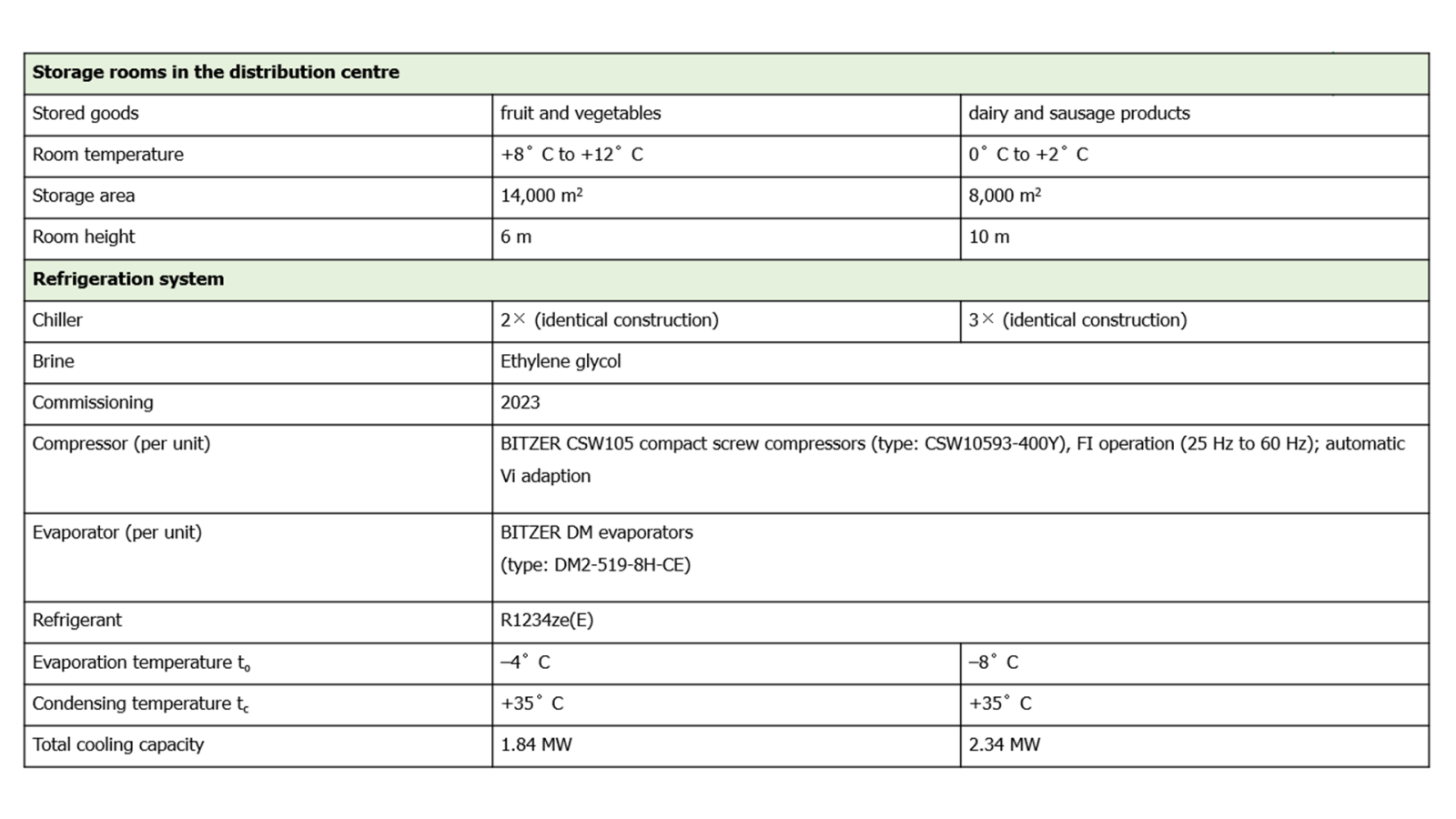

Due to the large quantities of perishable food, strict requirements for storage temperatures and the cold chain must be met, which means that the refrigeration system must ensure not only precise temperature control but also highly reliable operation. The various product groups are stored in two rooms that require different temperatures within the normal cooling range: fruit and vegetables, stored over an area of 14,000 m², need temperatures between +8°C and +12°C. Dairy and sausage products are stored over an area of 8,000 m² at 0°C to +2°C. This storage area is directly connected to the picking area of the logistics centre, which has a room temperature of +12°C to +15°C to ensure a smooth flow of goods. The picking area for dairy and sausage products is 1,572 m², while the picking area of fruit and vegetables is 2,351 m². The special feature: the picking area can be used as an extension of the storage area during peak times, with temperatures adjusted accordingly.

For the cooling of the storage rooms, FRIGOVENETA planned and installed five chillers. Three of the chillers produce brine at a temperature of –8°C for cooling dairy and sausage products, with a total cooling capacity of 2.34 MW. Two of the chillers supply the fruit and vegetable storage area with a total cooling capacity of 1.84 MW, maintaining a brine temperature of +2°C. The redundant design for both storage rooms ensures high system availability at all times. Additionally, the chillers for the two storage rooms are connected on the brine side by a bypass line, allowing for switching between rooms in the event of a unit failure, ensuring the other room can be supplied as needed. This minimises the loss of cooling capacity.

Strict safety requirements

The chillers proved to be the ideal solution, as the stringent safety requirements of the end customer necessitated a system design without direct evaporation of the refrigerant. Safety-relevant aspects also had to be considered for the refrigerant. After careful evaluation, the choice fell on the A2L refrigerant R1234ze(E), as it is classified as non-toxic and has a low global warming potential (GWP = 6). All refrigerant-carrying parts of the FRIGOVENETA system are housed in a separate machine room. On the roof of the distribution centre, V-shaped dry coolers dissipate heat energy to the environment. In agricultural surroundings, the dry coolers have a reserve area to ensure safe and efficient heat dissipation even at high ambient temperatures and where there is increased contamination from dust due to nearby agricultural activities.

CSW105 compact screw compressors: efficient and powerful

Due to the high performance requirements of the system, driven by the large storage areas and the volume of goods, FRIGOVENETA chose the BITZER CSW105 series compact screw compressors for the chillers. FRIGOVENETA and BITZER have successfully collaborated on many projects. ‘We are particularly satisfied with the screw compressor portfolio of BITZER and have found nothing comparable on the market in the performance size of the CSW105. The products, comprehensive service, and delivery times make BITZER a good partner,’ says Tobia De Vincenzi, Remote Monitoring Center at FRIGOVENETA.

The compressors of the CSW105 series can be operated with speed control in the range of 25 to 60 Hz using an external frequency inverter. Thanks to the IQ MODULE, automatic Vi adjustment is enabled in the special frequency inverter mode. This ensures that the compressors operate with optimal Vi at all operating points, making the compression process nearly loss-free. The compressors generate the required cooling capacity at each operating point with minimal power consumption, offering maximum efficiency both at full and part load. Additionally, the compressors feature an integrated oil separator and suction gas cooled motor, allowing for compact system dimensions, which is crucial given the limited space in the machine room for the refrigeration technology of the storage rooms. Optimally matched to the compressors, FRIGOVENETA uses evaporators from the BITZER DM series in the chillers. The dry expansion evaporators have a patented refrigerant distribution system and guarantee high heat transfer performance. The flexibility in the configuration of the DM series allowed FRIGOVENETA to choose the optimal design for the project requirements.

Remote access to operating data

FRIGOVENETA’s service offering includes comprehensive aftersales support for the end customer, ensuring long-term reliability. For this, experts need detailed insights into the operating data of the compressors – even remotely. Thanks to the IQ MODULE, this is effortlessly possible. The compressors are connected to the BITZER Digital Network (BDN) via a gateway on board in the switch cabinet, allowing FRIGOVENETA to access detailed operating data of the compressors at any time for troubleshooting with quick evaluations and optimisations through the online platform myBITZER.

Since 2023, FRIGOVENETA’s refrigeration system has been running smoothly in the new supermarket distribution centre. The efficient and reliable cooling keeps the food in the warehouse fresh and safe, ensuring it is delivered to the discount stores in optimal condition. ‘We are pleased that our chillers not only improve the efficiency and reliability of the cold chain, but also that the operator benefits from reduced operating costs thanks to the system’s low energy consumption,’ summarises Roberto Mambrin, Key Account Manager at FRIGOVENETA.