HS. and OS. series: ECO pipe layout and ECO pipe sizes

Pipe sizes

Kit numbers for adapter and shut-off valve, connection sizes of the ECO suction gas lines or ECO shut-off valves:

- AT-320: Connections and shut-off valves for BITZER compressors

Pipe layout

Risk of damage to the compressor caused by liquid slugging and lack of oil!

Avoid migration of oil or refrigerant into the compressor (wet operation) and oil traps/oil pockets in the system!

- Carefully plan pipe layout and system design.

- Arrange the liquid subcooler / intermediate pressure vessel below the compressor.

- Route the pipeline from the ECO connection first upwards and then in a bend again downwards.

- In systems with high refrigerant charge: Install the suction accumulator upstream of the suction gas connection of the compressor.

- For continuous oil return, always ensure the minimum required gas flow velocity in the system.

For compressors OS.85 .. 105 and HS.95, the ECO connection is located at the top of the compressor housing, so that no swan neck pipe for protection against oil migration is required. Route the line from the connection horizontally or downwards.

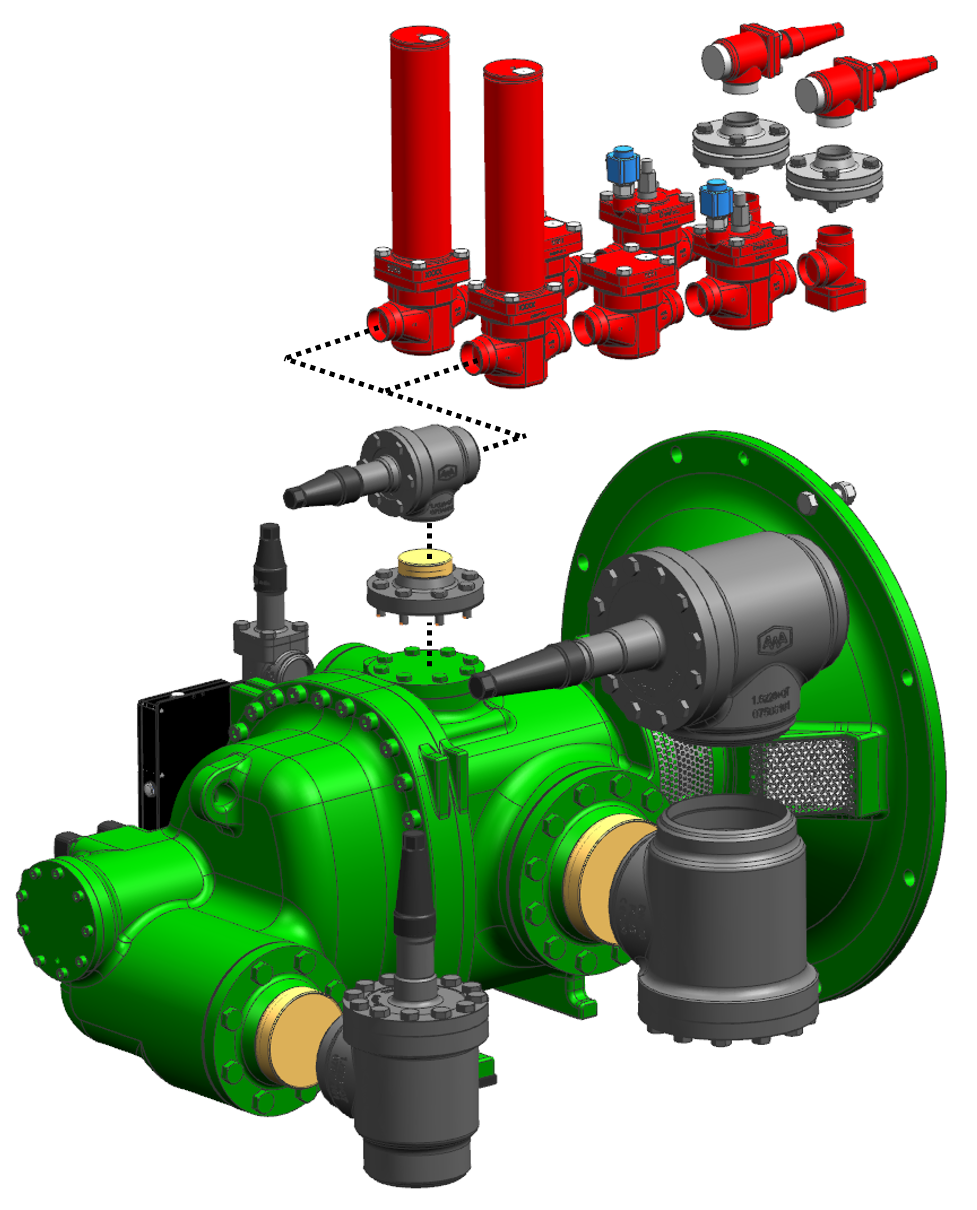

For compressors OS.53 .. OS.74 and HS.53 .. HS.85, the ECO connection is attached to the bottom of the compressor. Therefore a swan neck pipe is required for protection against oil migration, see the following figures.

Risk of pipe fractures and leakages on compressor and system due to vibrations.

Avoid critical pipe lengths and/or install a muffler.

- Solder the ECO suction gas line directly into the ECO shut-off valve.

- In systems with high refrigerant charge: Install suction accumulator upstream of the suction gas connection of the compressor.

- For continuous oil return, always ensure the minimum required gas flow velocity in the system.

Reduced system efficiency due to ambient heat gains in the liquid line!

Insulate the liquid line between the liquid subcooler and the expansion valve of the evaporator!

Mounting the ECO shut-off valve

OS.85 Description

HS.85 Description