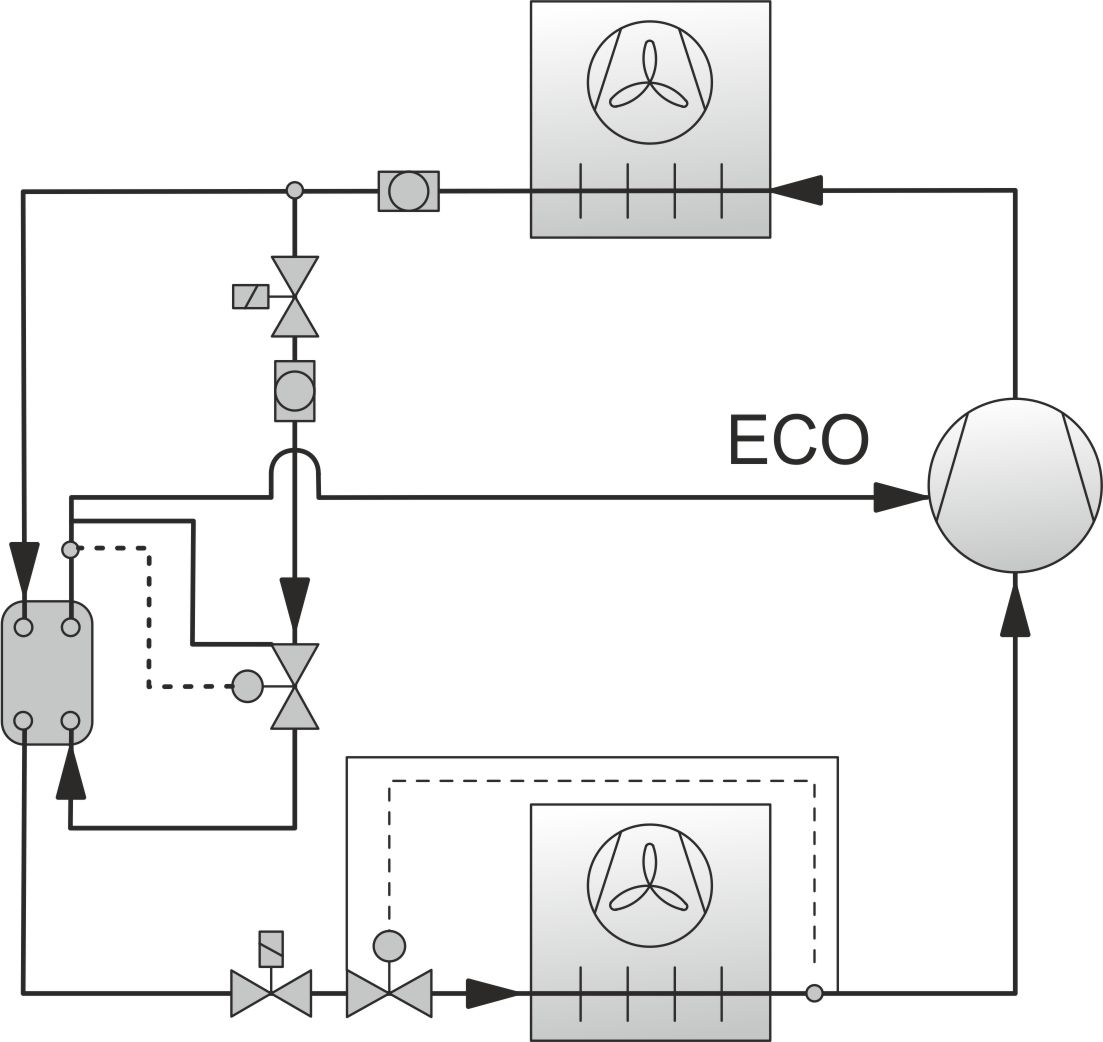

ECO operation with liquid subcooler

The additional heat exchanger (here: liquid subcooler) subcools the liquid refrigerant by feeding part of the refrigerant coming from the condenser into the subcooler in counterflow by means of an expansion device and evaporating it with absorption of heat. The superheated vapour is extracted at the ECO connection of the compressor and mixed with vapour coming from the evaporator.

The pressure of the subooled liquid refrigerant is equal to the condensing pressure level. This is why the pipeline to the evaporator does not require any special features with the exception of isolation. However, preferably, the liquid subcooler should be arranged below the compressor, in order to avoid the return of oil or liquid refrigerant to the compressor during standstill periods.

Reduced system efficiency due to ambient heat gains in the liquid line!

Insulate the liquid line between the liquid subcooler and the expansion valve of the evaporator!