Avoiding damages due to critical pipe lengths

Positive displacement compressors do not convey the refrigerant completely continuously: high pressure and low pressure are superimposed by pulsations. The pulsations propagate in the pipework at the speed of sound of the refrigerant vapour and can be reflected at 90° pipe bends, closed ends or valves. Unfavourably selected straight pipe lengths up to the point of reflection result in resonances and standing waves. These can lead to very high pressure peaks, large forces on the pipework and significant temperature increases. Pipe ruptures due to these effects are possible.

To avoid pipe bursts, critical pipe lengths should be calculated and then avoided in the system as straight pipe sections, especially in the pressurised gas line and economiser line. Half the pipe length should also be avoided: it corresponds to the second harmonic with twice the frequency.

The calculation requires:

- The speed of sound in the refrigerant vapour at the pressures and temperatures of the respective system. It can be determined using refrigerant substance data programmes such as ASEREP from Asercom or RefProp from NIST.

- The frequency of the pulsations. It depends on the compressor design and the frequency of the supply voltage, i.e. it is variable in the case of frequency inverters.

The following applies to BITZER compressors:

Compressor design | Speed | Pulsation | |

|---|---|---|---|

Semi hermetic reciprocating compressors | n ≈ 0,5 x f | fp = n x z | 4 pole motors, |

Screw compressors | n ≈ f | fp = n x z | 2 pole motors, |

Scroll compressors | n ≈ f | fp = n | 2 pole motors, |

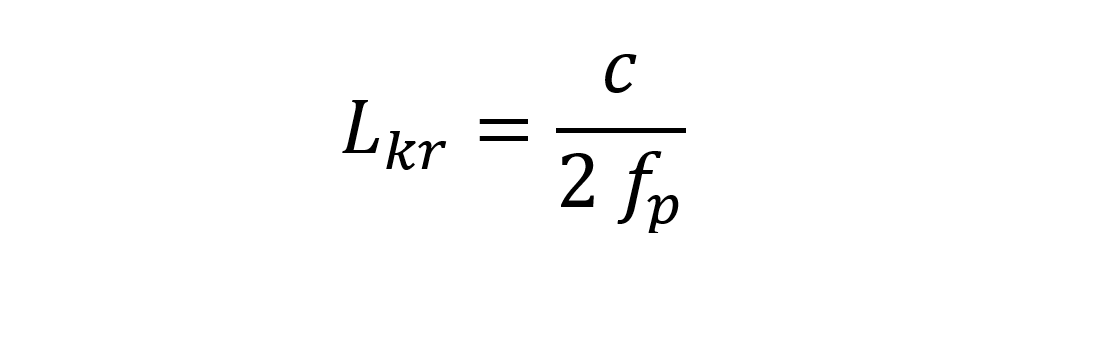

The critical pipe lengths can then be calculated as follows:

c: speed of sound in m/s

Example for screw compressors with frequency inverter:

z = 5; f = 20 .. 60 Hz; fp = 100 .. 300 (600) Hz

tc = 60°C, tV2 = 100°C, R1234yf

Lkr = 0.72 .. 0.24 (0.12) m

Example for 4 cylinder reciprocating compressors with frequency inverter:

z = 4; f = 25 .. 70 Hz; fp = 100 .. 280 (560) Hz

tc = 50°C, tV2 = 90°C, R290

Lkr = 2.39 .. 0.85 (0.43) m

A range of ±15% should also not be used around the calculated values for the critical pipe length in order to cover uncertainties, e.g. when determining the temperature and pressure and the slip of the asynchronous motor. In the examples above, the number in brackets corresponds to the harmonics with double frequency. If certain pipe lengths cannot be avoided, it is possible to calculate which frequency ranges must be suppressed.

The reflection can be largely suppressed by

- using two 45° bends instead of one 90° bend,

- bent pipes with a large bending radius of >24 times the pipe diameter and

- 45° joints.

Well-tuned pulsation mufflers in the discharge gas line and the economiser line can often reduce the pulsations sufficiently.