Design example of an ejector in a low lift application

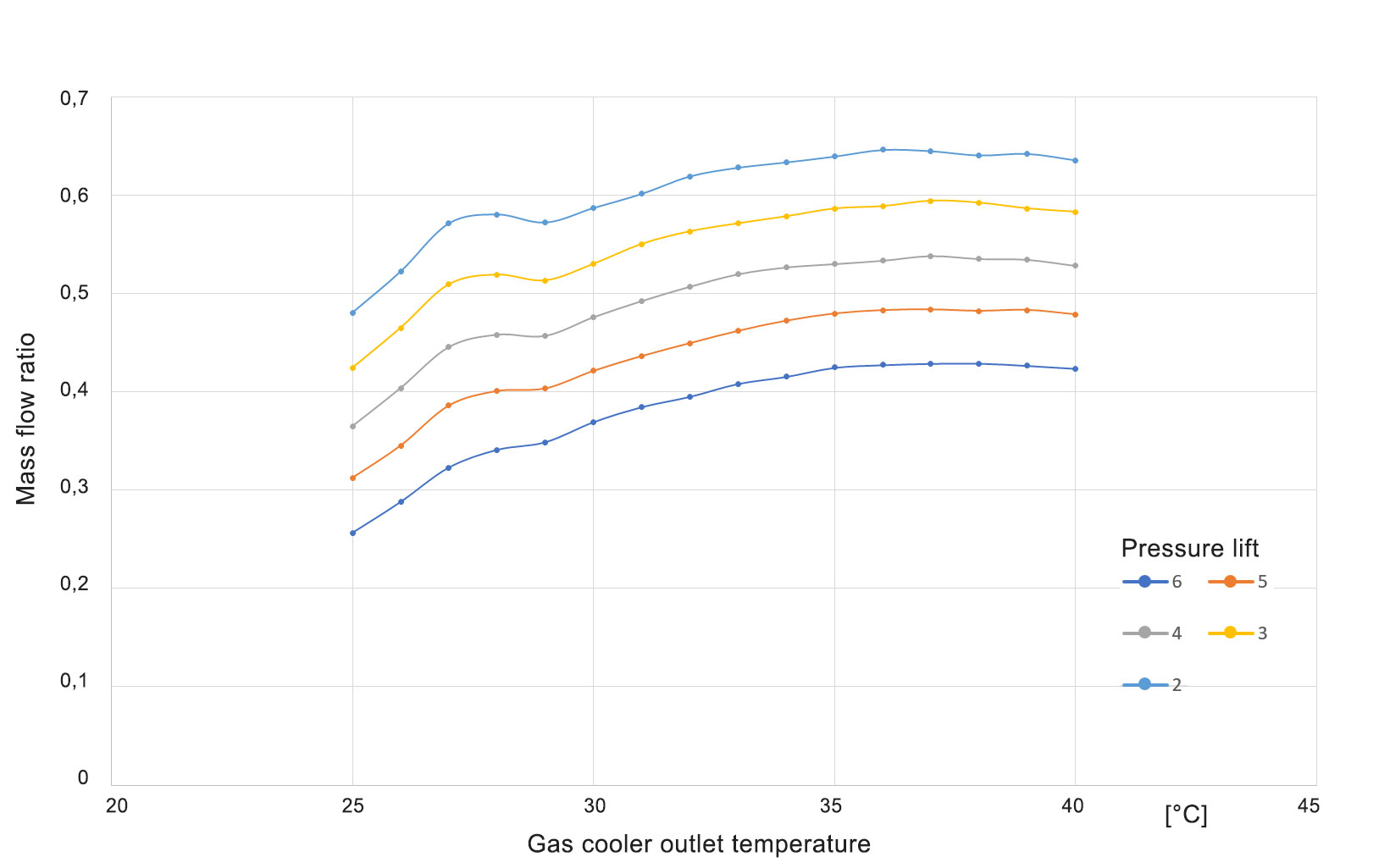

In a low lift application, the mass flow ratio is the essential selection criterion. The ejectors circulate the refrigerant in a similar way to a refrigerant pump. The goal is to increase the pressure only to the extent allowed by the mass flow ratio of the pumping operation.

From the characteristics of the selected ejector results the suction mass flow at the given high pressure, motive mass flow rate and intermediate pressure. The intermediate pressure is determined by the suction pressure control of the compressor.

In the following example, a single-stage system with one ejector is to be calculated:

Boundary conditions:

- Gas cooler outlet temperature (tgc) at the design point: 35°C

- High pressure, absolute (pHP): 89 bar

- Evaporation temperature in the medium temperature compressor stage (to MT): -8°C

- Cooling capacity of the medium temperature compressor stage (Qo MT): 60 kW

- Medium pressure, absolute (estimated): 33 bar

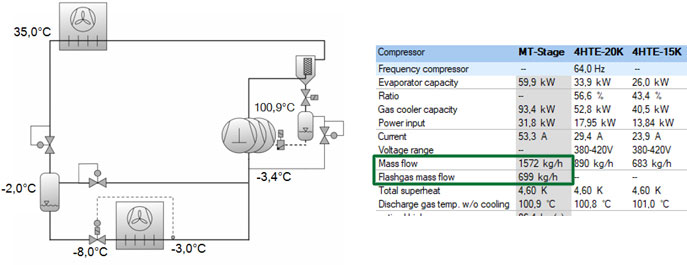

First, a system without ejector with a standard superheat control is calculated in BITZER SOFTWARE under "R744 booster selection" (see following figure). The intermediate pressure is selected approx. 5 bar above the evaporation pressure. According to a first estimate, this corresponds to the pressure lift of the system with ejector.

With these assumptions, the first step is to calculate the ejector's mass flow to be delivered to achieve the cooling capacity of 60 kW. Due to the separation in the intermediate pressure vessel, the net mass flow that flows through the evaporator and is sucked in again by the ejector is the total mass flow minus the flash gas mass flow; in this example, this is 1572 kg/h - 699 kg/h = 873 kg/h.

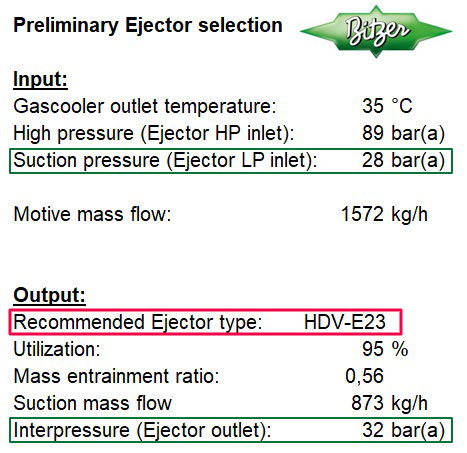

Based on the mass flow that must flow through the evaporator to achieve the cooling capacity of 60 kW, the necessary delivery rate of the compressors can be determined via the mass flow ratio of the ejector. The HDV-E23 ejector pre-selected in the BITZER calculation tool has a mass flow ratio of 0.56 and a pressure stroke of 4 bar at a high pressure of 89 bar and a motive mass flow of 1572 kg/h.

The recommended ejector HDV-E23 can therefore suck in 873 kg/h and deliver to an intermediate pressure that is 4 bar higher.

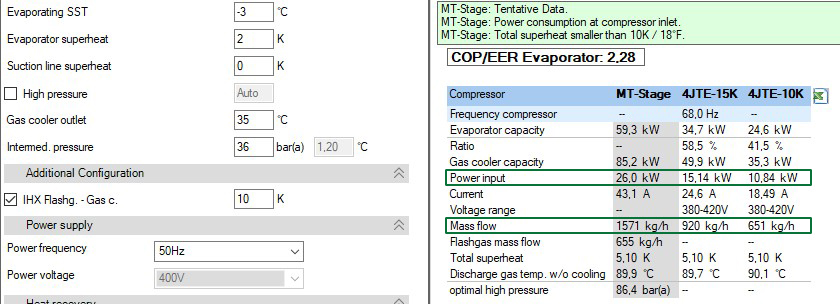

Smaller compressors can now be selected due to the increased suction pressure. The cooling capacity shown in the new selection is irrelevant. The calculation is only used for the new compressor configuration based on the motive mass flow for the ejector at the higher pressure level and to determine the power consumption. The compressors would now have to deliver a mass flow of 1572 kg/h from the intermediate pressure vessel at 32 bar suction pressure (-3°C) (see figure below). The corresponding power consumption is the new compressor power consumption of the system with ejector.

COP

The COP of the flash gas bypass system is Qo / Pe = 59.9 kW / 31.8 kW = 1.9

The COP of the system with ejector is Qo / Pe = 59.9 kW / 26 kW = 2.3

It must be kept in mind that the advantage of the approx. 3 K higher evaporation temperature due to operation with flooded evaporator has not yet been taken into account.