Overview of connection types

The following figures show the most common types of connections:

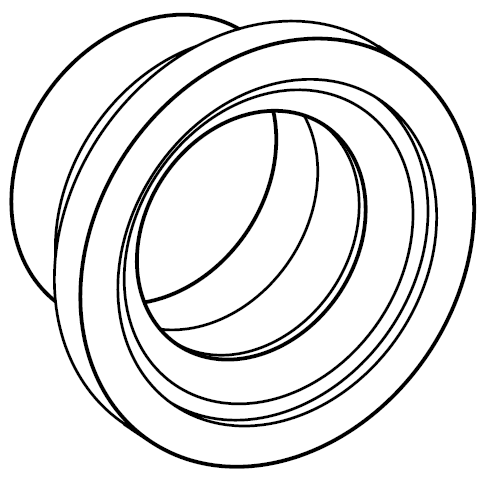

Brazing and welding bushes

The bushes are made of steel and are suitable for A1, A2, A2L and A3 refrigerants as well as R717. Most are suitable for brazing and welding, some for only one of the two. They can sometimes be combined with valves (see below), in which case the valve is located between the compressor and the bush, i.e. the bush is the connection towards the pipe.

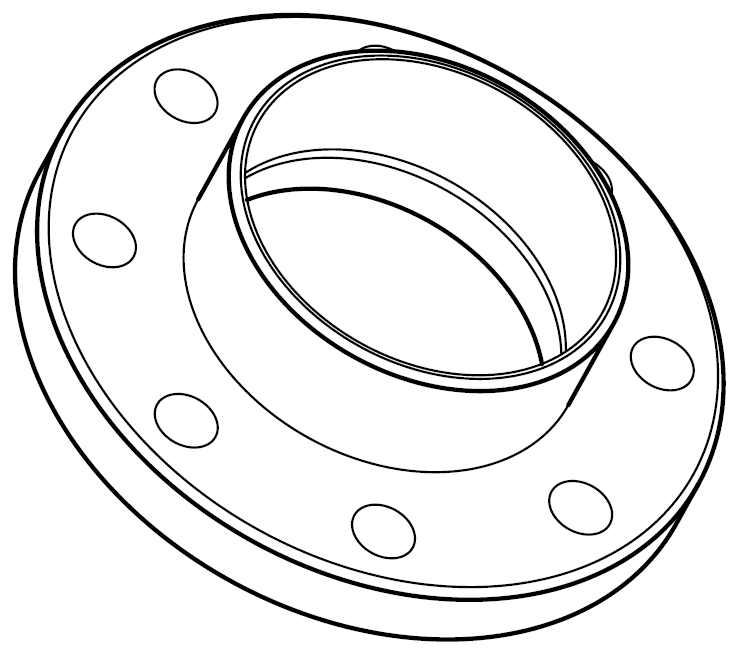

Brazing / welding flanges

The flanges are made of steel and are suitable for A1, A2, A2L and A3 refrigerants as well as R717. They are suitable either for brazing or for welding. Similar to bushes, they can sometimes be combined with valves, in which case the valve is located between the compressor and the flange, i.e. the flange is the connection towards the pipe.

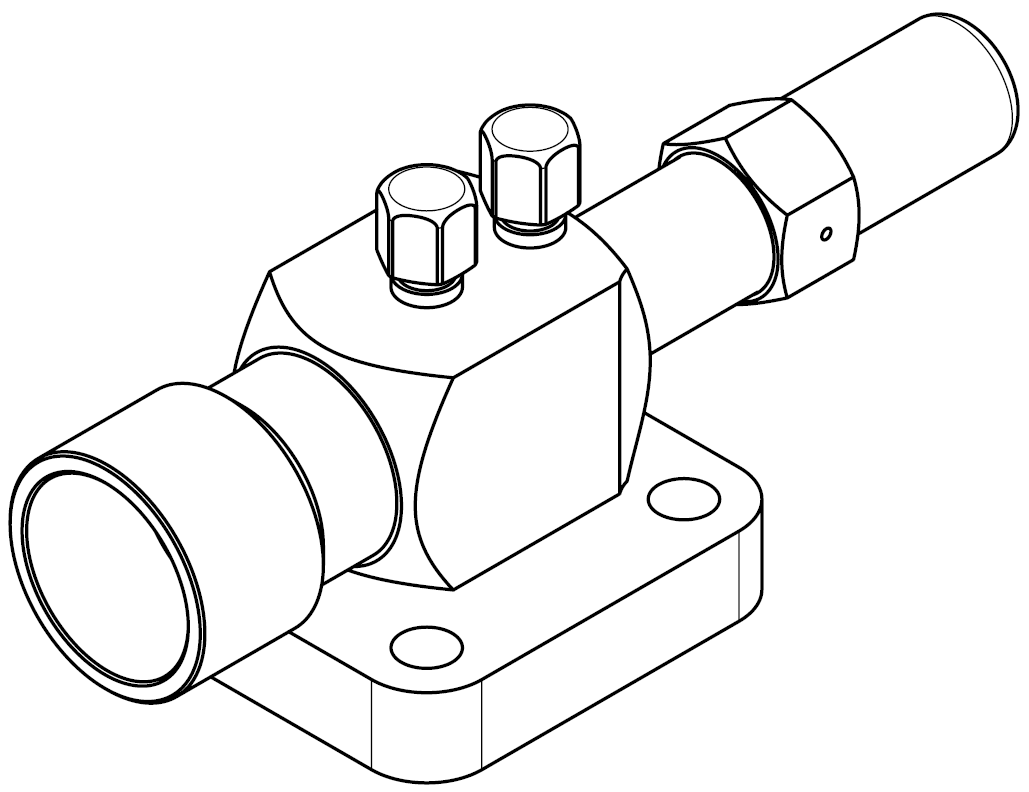

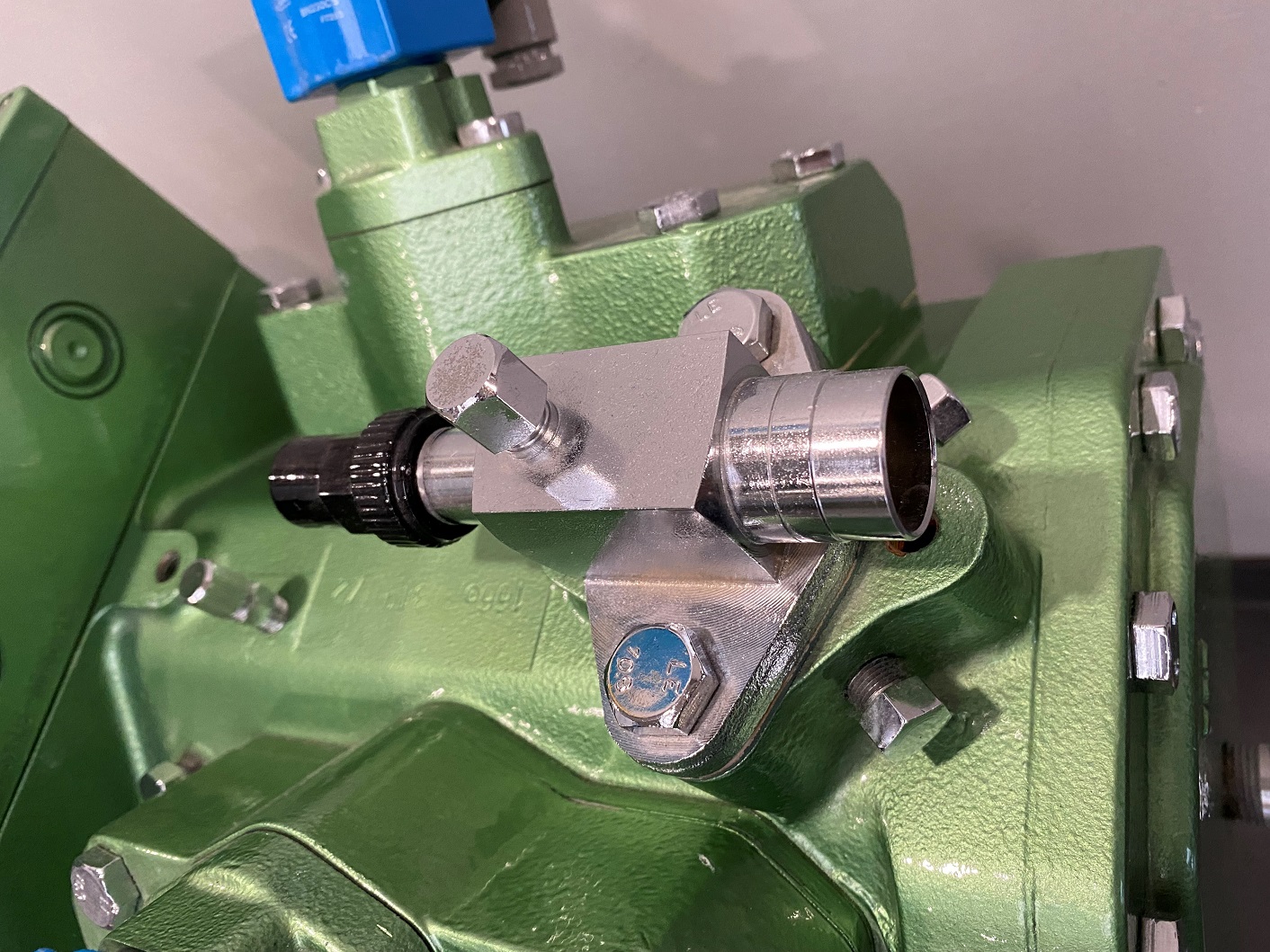

Valve body with brazing / welding connection to the pipe

The valve body itself has a connection to which the pipe is brazed or welded. Many of these valves are suitable for brazing and welding, some for only one of the two. They are usually made of steel and have 1 or 2 maintenance connections, which may be positioned differently. Towards the compressor, most valves have a flanged connection, threaded connections are rarer.

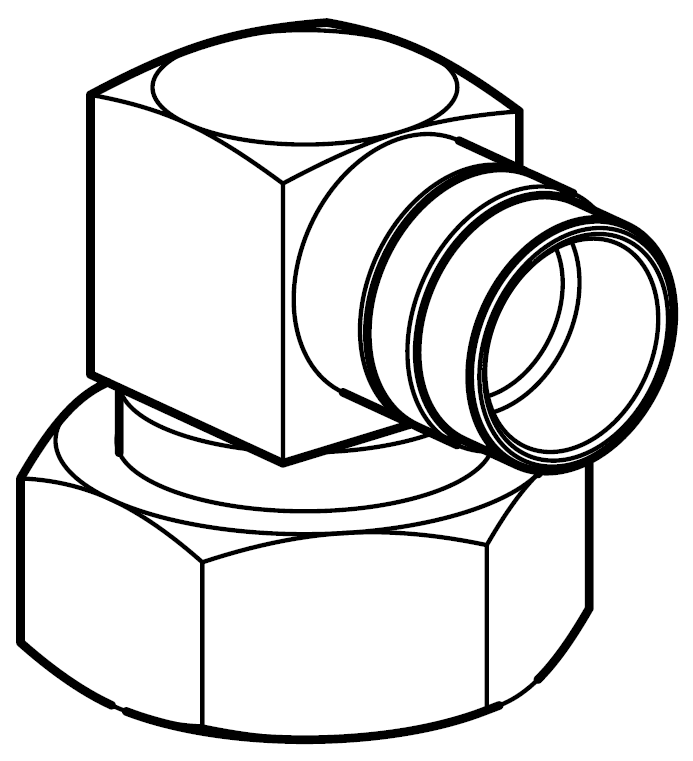

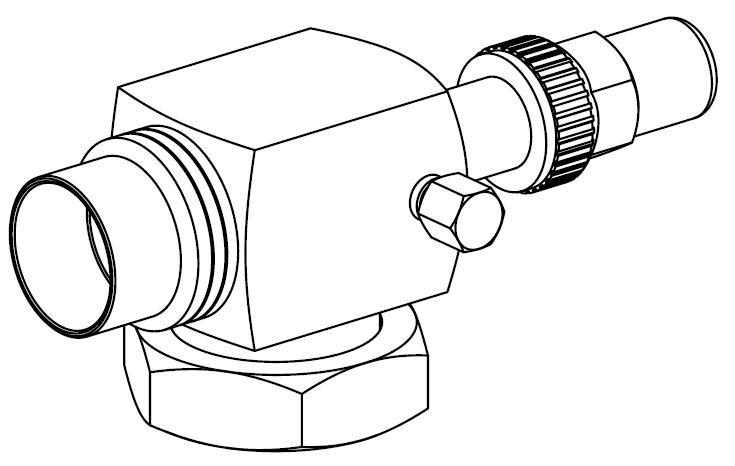

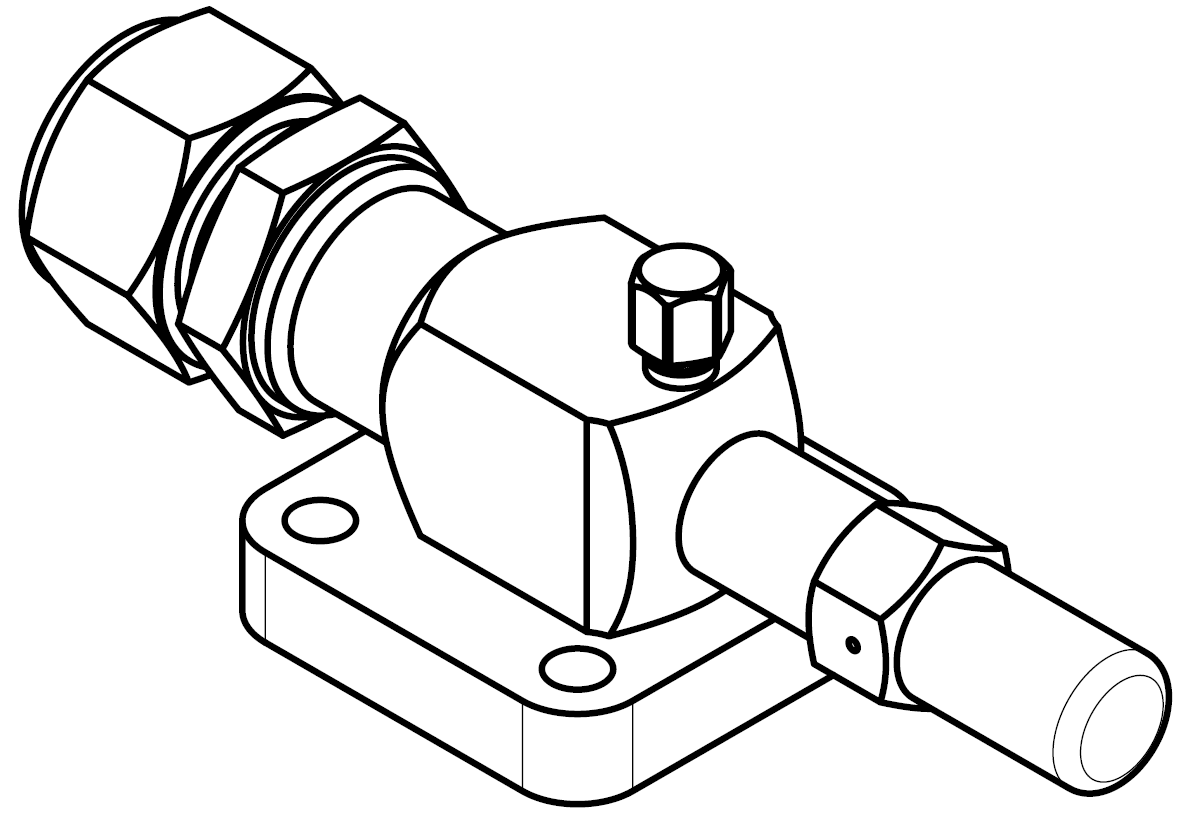

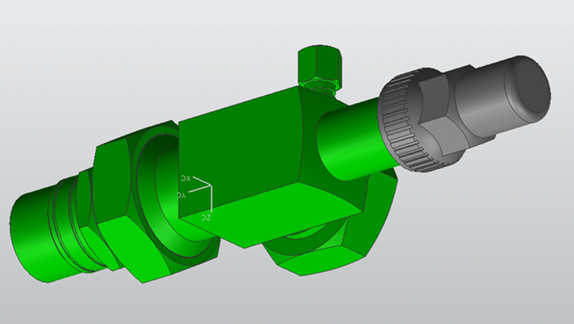

Valve body with compression fitting to the pipe

Valve body with additional bush towards the pipe

Some valves are combined with a bush (or other connection piece), then this forms the connection to the pipe.

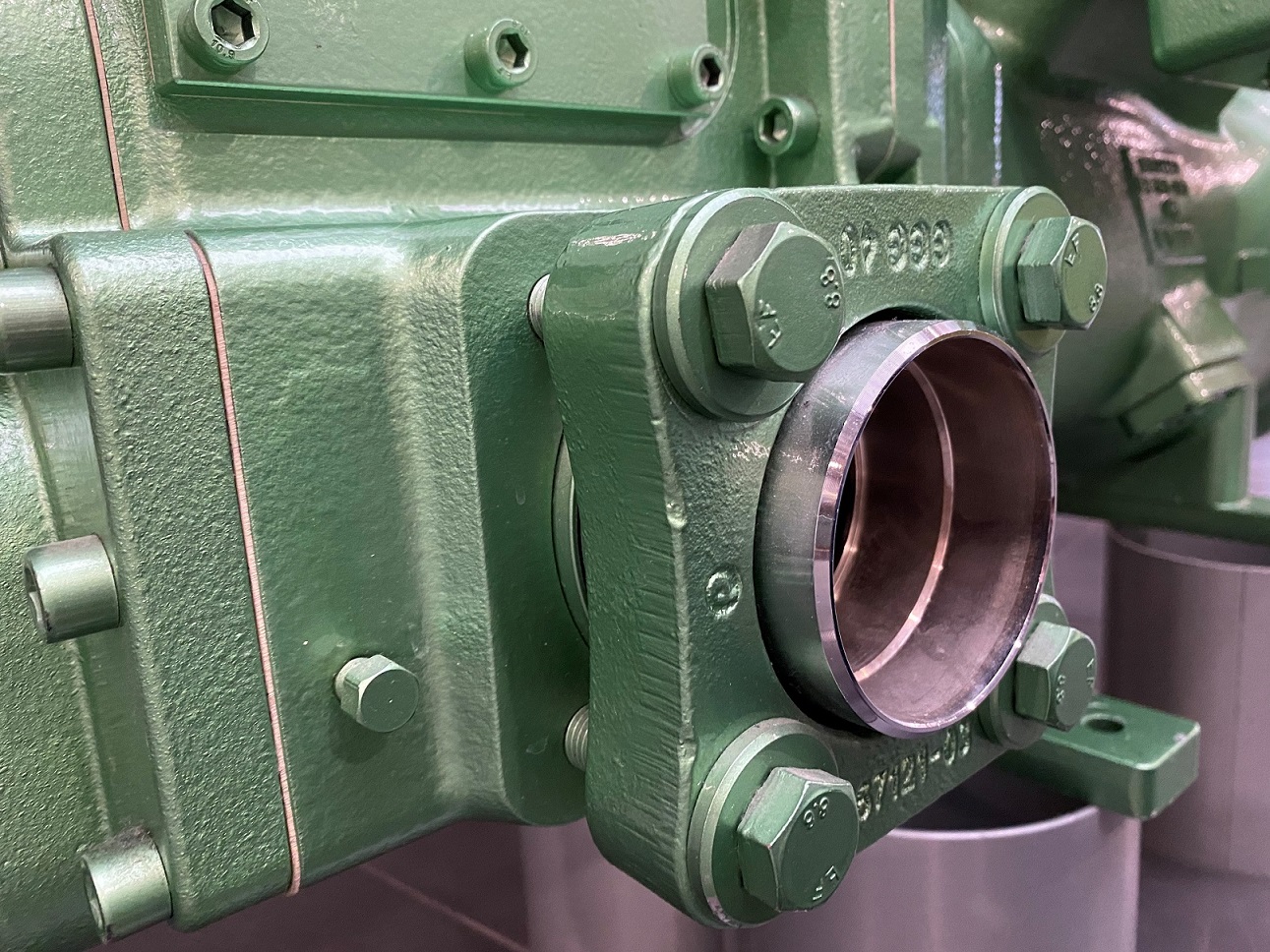

Valve body with bush / flange and counter flange

These (usually larger) valve bodies made of grey cast iron have a flange connection to the compressor. For the connection to the pipe, a bush or flange must be installed between the valve and the counter flange - often different ones fit here on the same valve body.

Above: valve fully open (spindle in back seal).

Below: valve fully closed (spindle in valve seat).

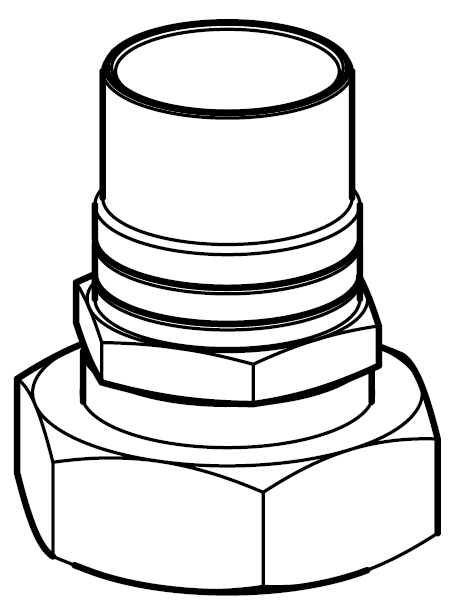

Pipe connection

These have e.g. a threaded connection to the compressor and a brazing connection to the pipe.