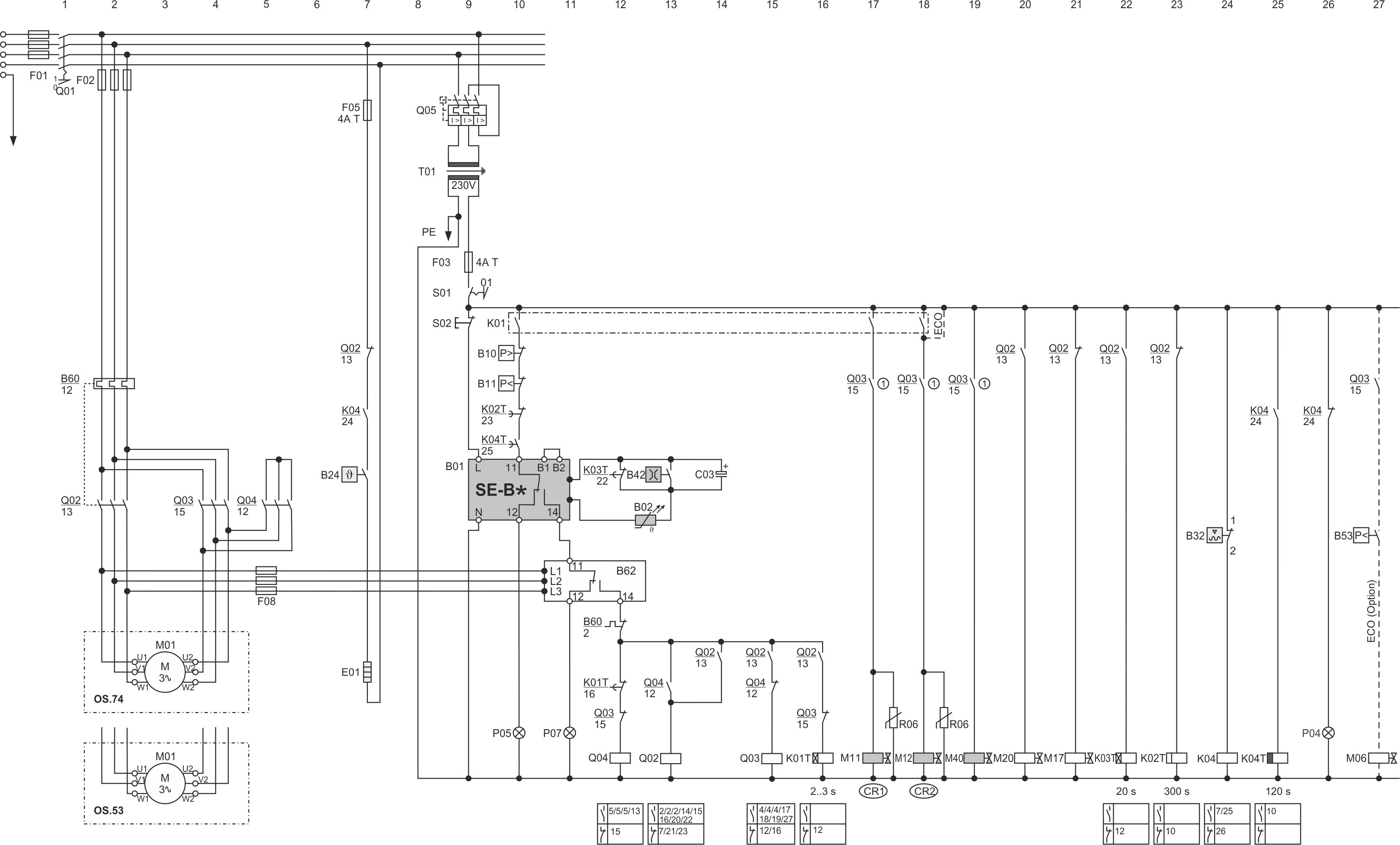

OS.53 .. 74 with SE-B*, Y/Δ start

The polarity of the orange connection cables on the SE-B* protective device must be determined with a measuring device.

In grey: options and components that are included in the scope of delivery of the oil separator.

(1): If the star-delta switching time exceeds 2 s, a time relay with max. delay time 2 s must be used instead of the normally open (NO) contacts Q03/15 in paths 17, 18 and 19.

For OS.53:

Correct direction of rotation for the compressor (viewed from compressor shaft end): clockwise, see also arrow on the compressor.

When looking from the compressor towards the motor, the motor obviously rotates in the opposite direction (counter-clockwise).

For OS.74:

Correct direction of rotation for the compressor (viewed from compressor shaft end): counter-clockwise, see also arrow on the compressor.

When looking from the compressor towards the motor, the motor obviously rotates in the opposite direction (clockwise).

Last revision of the diagram:

13.10.2025

Abbr. | Component |

|---|---|

B01 | Compressor protection device |

B02 | Discharge gas temperature sensor |

B03 .. 08 | Temperature sensors in motor windings |

B10 | High pressure switch |

B11 | Low pressure switch |

B14 | Additional protection device for oil monitoring |

B21 | Optional temperature sensor |

B24 | Oil thermostat |

B30 | Oil level switch |

B32 | Oil level switch at oil separator |

B41 | Oil filter monitoring |

B42 | Oil flow switch |

B50 | High pressure transmitter |

B51 | Low pressure transmitter |

B53 | ECO switch-on |

B60 | Overload protective device |

B61 | Overload protective device for second part winding |

B62 | Rotation direction monitoring |

C03 | Electrolytic capacitor |

E01 | Oil heater |

E02 | Terminal box cover heater |

F01 | Main fuse |

F02 | Compressor fuse |

F03 | Control circuit fuse |

F04 | Fuse of compressor protection device or compressor module |

F05 | Fuse of oil heater |

F07 | Fuse of terminal box cover heater |

F08 | Fuse of rotation direction monitoring |

K01 | Superior controller |

K01T | Time relay for part winding start or for star-delta start |

K02T | Time relay for minimum shut-off period of compressor |

K03T | Time relay for oil supply fault |

K04 | Auxiliary relay for oil monitoring |

K04T | Time relay for oil level switch |

K05T | Time relay for oil supply monitoring |

K06T | Time relay for capacity regulator |

M01 | Compressor motor |

M06 | SV for economiser (ECO) |

M11 | SV for capacity regulator 1, CR1, CR+, CRII-2 or start unloading |

M12 | SV for capacity regulator 2, CR2, CR- or CRII-1 |

M13 | SV for capacity regulator 3, CR3 or CRII-3 |

M14 | SV for capacity regulator CR4 |

M17 | SV for standstill bypass |

M20 | SV for liquid line |

M40 | SV for oil injection |

P03 | Light: time delay is activ |

P04 | Light: oil supply fault |

P05 | Light: compressor fault |

P07 | Light: wrong rotation direction |

P18 | Light: oil filter fault |

Q01 | Main switch |

Q02 | Contactor for first part winding (PW) or main contactor (Y/Δ) or compressor contactor (DOL) |

Q03 | Contactor for second part winding (PW) or delta contactor (Y/Δ) |

Q04 | Star contactor (Y/Δ) |

Q05 | Control transformer fuse |

R06 | Interference suppressor (if required, e. g. from Murr Elektronik) |

S01 | Control switch (on-off) |

S02 | Reset of compressor safety chain |

S18 | Reset of oil filter monitoring |

T01 | Control transformer (example for 230 V, required according to EN60204-1) |

Technical documents for further information: