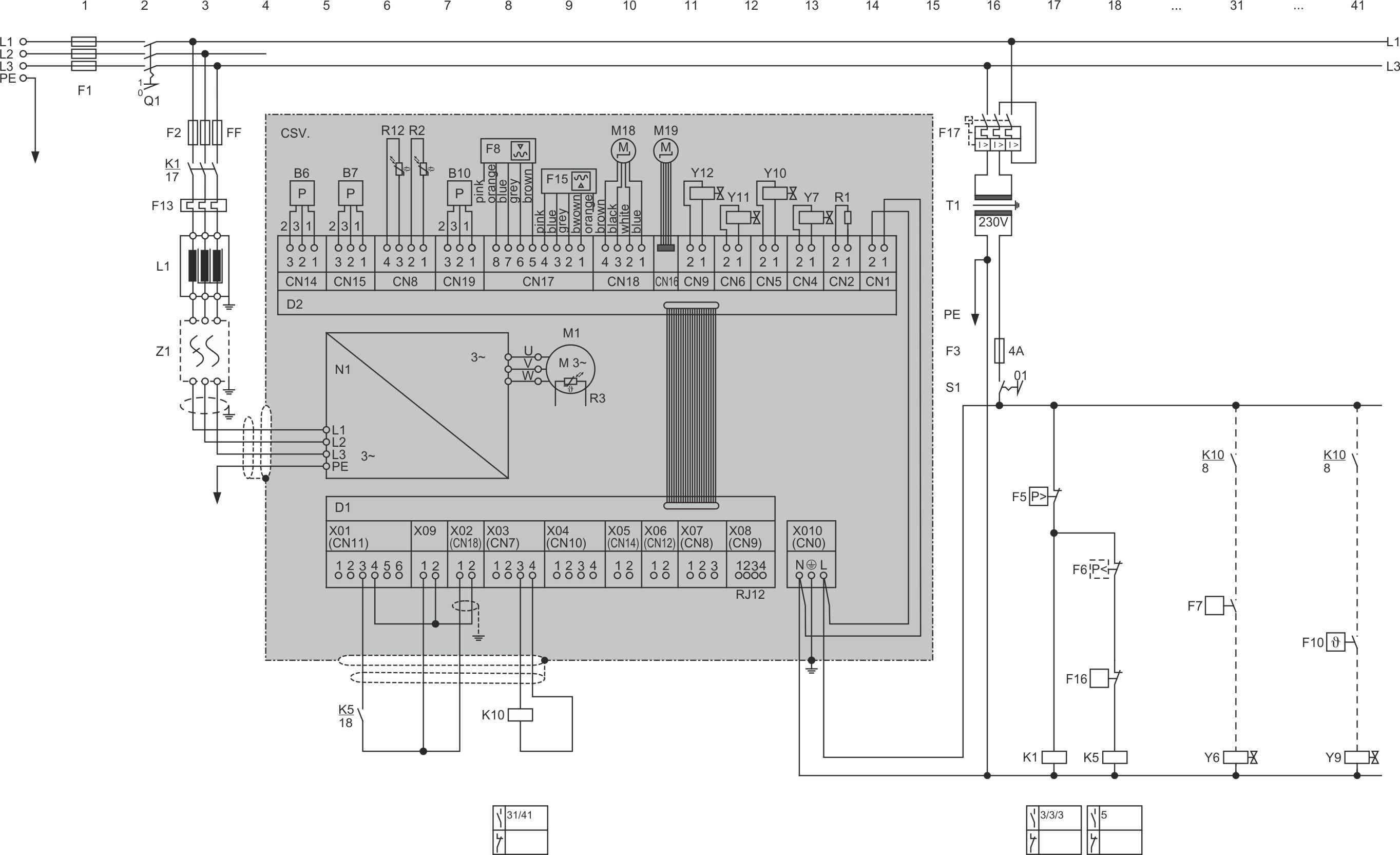

CSV. without STO

Last revision of the diagram:

12.02.2021

Abbr. | Component | |

|---|---|---|

B6 | High pressure transmitter ① | |

B7 | Low pressure transmitter ① | |

B10 | Pressure transmitter at cooling plate outlet | |

D1 | Control board of the FI ① | |

D2 | Extension board of the FI ① | |

F1 | Main fuse | |

F2 | Compressor fuse | |

F3 | Control circuit fuse | |

F5 | High-pressure switch | |

F6 | Low pressure switch | |

F7 | Cut-in delay “ECO" | |

F8 | Oil level switch (minimum oil level)① | |

F10 | Control thermostat for oil cooler | |

F13 | Overload protective device | |

F15 | Oil level switch (maximum oil level) | |

F16 | Relay for protective functions upon customer request (frost protection, water flow, etc.) | |

F17 | Control transformer fuse | |

K1 | Compressor contactor | |

K5 | Auxiliary contactor “compressor is ready-to-operate” | |

K10 | Auxiliary relay “compressor is running” (for message to system controller) | |

L1 | Line reactor ② | |

M1 | Compressor motor ① | |

M18 | Electronic evaporator pressure valve for cooling plate | |

M19 | Electronic expansion valve for cooling plate | |

N1 | Frequency inverter (FI) ① | |

Q1 | Main switch | |

R1 | Oil heater ① | |

R2 | Oil temperature sensor (NTC) ① | |

R3 | Temperature sensor in the motor (NTC) ① | |

R12 | Temperature sensor at cooling plate outlet | |

S1 | Control switch (on/off) | |

T1 | Control transformer (example for 230 V, required according to EN60204-1) | |

Y6 | Solenoid valve "ECO" | |

Y7 | Solenoid valve “LI” (option for CSVH) ② | |

Y9 | Solenoid valve “oil cooler line” | |

Y10 | Solenoid valve “FI cooling” ① | |

Y11 | Solenoid valve "Vi slider +" ① | |

Y12 | Solenoid valve "Vi silder -" ① | |

Z1 | RFI filter ② | |

① | Component included in the extent of delivery of the compressor | |

② | Component can be added as an option to the compressor’s extent of delivery. It can be retrofitted. |

Technical documents for further information: