Oil level monitoring OLC-K1

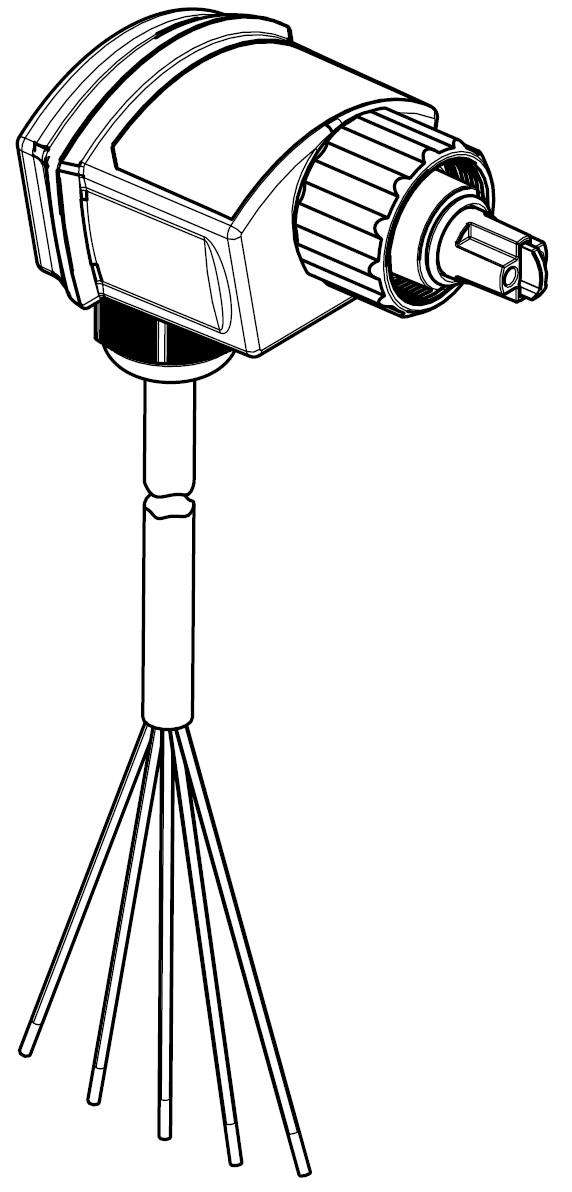

OLC-K1 is an opto-electronic oil level monitoring using infrared light. It consists of

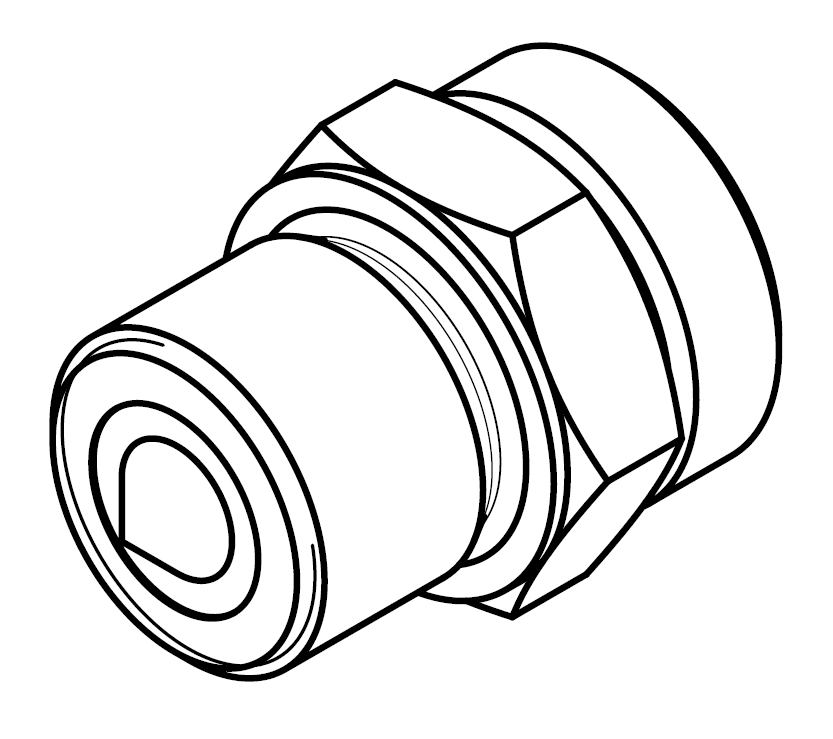

- a prism unit (screwed into the bearing cover) and

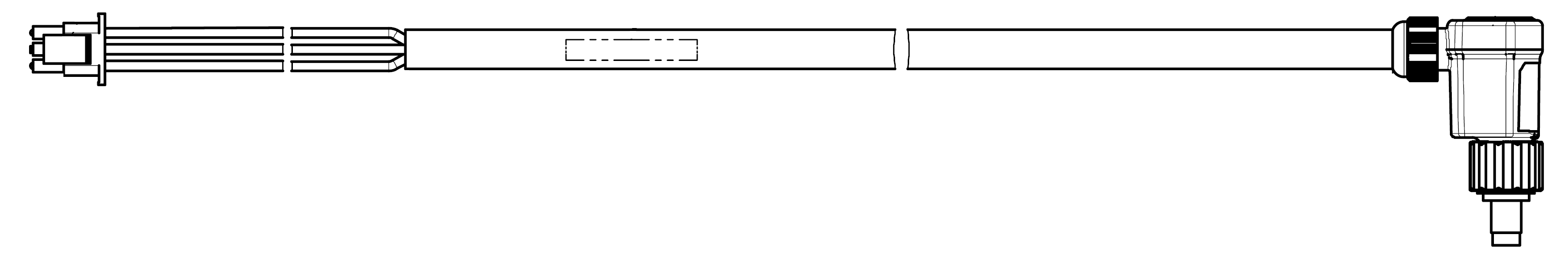

- an opto-electronic unit (screwed into the prism unit, is integrated into the control of the system).

The oil level monitoring activates 90 s after compressor start. This time bridges any oil fluctuations due to starting conditions. During operation, the compressor is switched off by the oil level monitoring after 5 s without a detectable oil level.

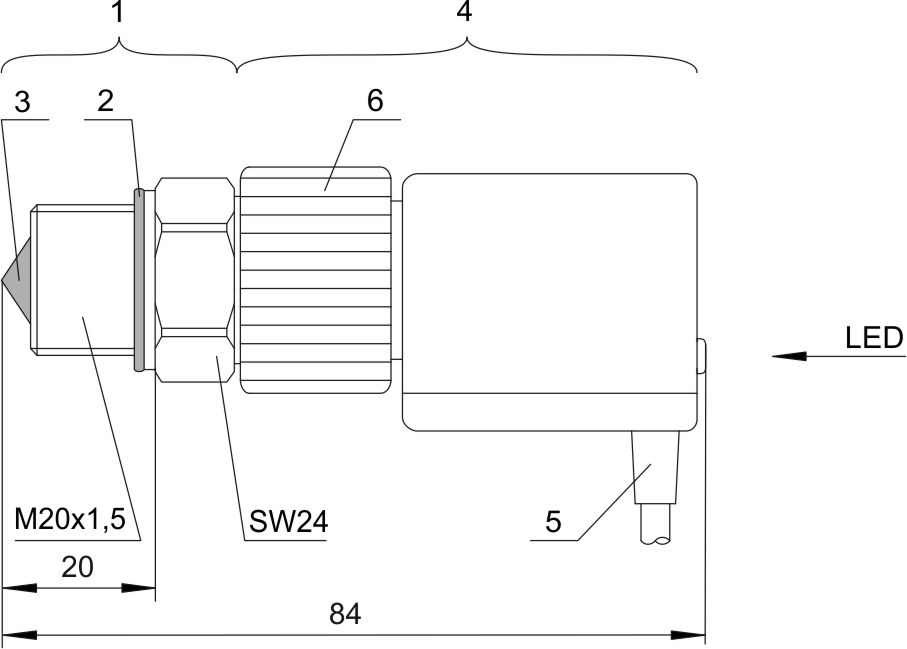

1: Prism unit

2: Seal (copper gasket ring)

3: Glass cone

4: Opto-electronic unit (360° rotatable)

5: Connection cable

6: Screwing cap

Variant | can be ordered as spare part assembly with part no. | Spare part assembly without prism unit | Prism unit | Opto-electronic unit |

|---|---|---|---|---|

230 V | 347 334 03 | 347 334 07 | 347 316 06 | 347 317 06 |

115 V | 347 334 04 | 347 334 08 | 347 316 06 | 347 317 07 |

24 V | 347 334 05 | 347 334 09 | 347 316 06 | 347 317 14 |

230 V | 347 334 91 | -- | 347 316 02 | 347 317 17 |

Examples for assemblies:

For details see

- AW-180: Oil level monitoring, mounting and electrical connection