Thermodynamics

In the heat exchangers, a two phase mix of gas and liquid usually reaches higher heat transfer coefficients at the same mass flow than a gas or liquid single phase flow. Thus, a higher surface heat flow resp. a lower temperature difference can be achieved. This results in more efficient heat exchangers with relatively low material use.

Vapour compression refrigeration with its heat transfer during two phase flow is so deep in the mind of refrigeration engineers and technicians that their wording usually is evaporating temperature and condensing temperature. These values come almost by themselves and correspond to the major driver in heat exchange, being the temperature differences. They also represent the pressures via the vapour pressure curve.

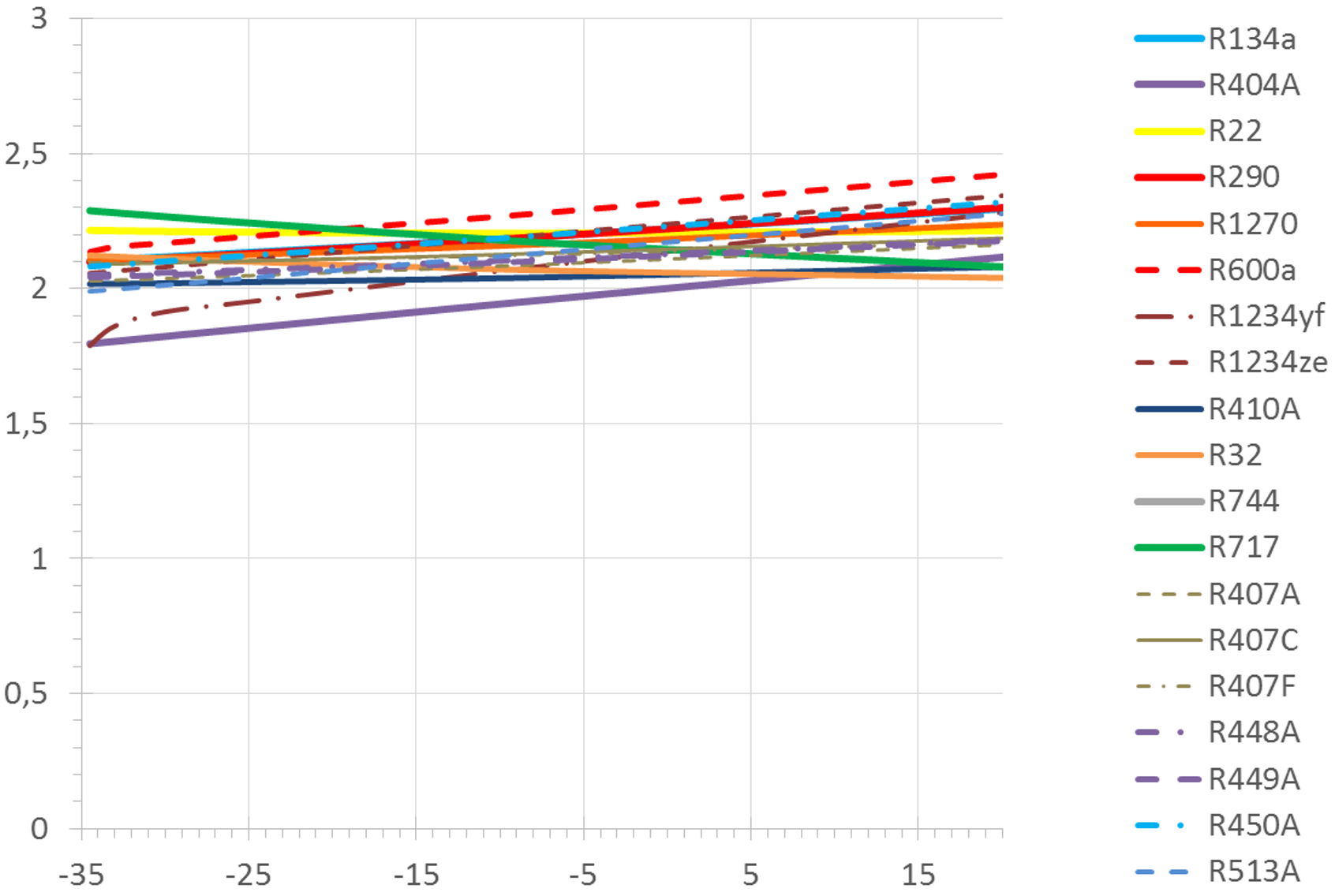

When choosing the refrigerant, energy efficiency should be among the determining factors. It can be calculated theoretically for the targeted operating conditions – or approximately via the performance data of compressors, with the refrigerants available for calculation with the chosen compressor.

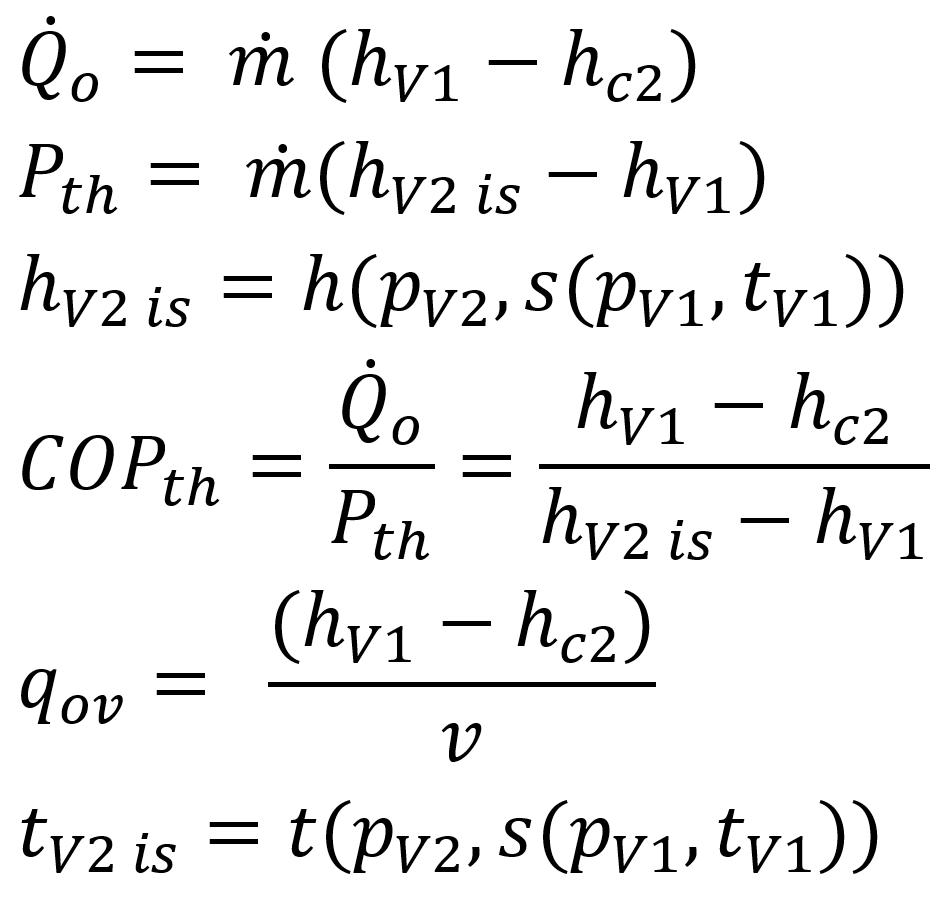

The theoretical calculation is done via the theoretical refrigeration capacity and the isentropic compression power:

Symbol | Explanation |

|---|---|

c | condenser |

COP | Coefficient of Performance |

h | specific enthalpy |

is | isentropic |

m | mass |

o | evaporator |

p | pressure |

P | power absorbed |

Q | heat amount |

qov | volumetric refrigeration capacity in J/m3 |

s | specific entropy |

th | theoretical |

t | temperature |

V | compressor |

v | specific volume in m3/kg |

v | index for volumetric |

1 | inlet |

2 | outlet |

The comparative theoretical evaluation can show better or worse performance of a single refrigerant in the targeted application, compared to a selection of other refrigerants. In the calculation of the theoretical efficiency COPth the massflow falls out, so only refrigerant property data determine the result.

This evaluation can be used for compressor driven systems. For absorption systems, some more inputs influence the results, not being dealt with in this document.

System design and operating conditions

When comparing efficiencies, it is important to respect that different refrigerants might need different system designs for optimum efficiency at given evaporating and condensing temperatures. Many refrigerants, like hydrocarbons and most hydrofluorocarbons, deliver the best COP with an internal liquid to suction line heat exchanger integrated in the system, while this heat exchanger lowers the efficiency for e.g. R717 (ammonia). Thus, it probably makes sense to calculate with different operating conditions and different system designs, before deciding for a refrigerant.