Electrics and electronics

The Performance Kits have been specially developed for already installed compressors in order to utilise the advantages of the BITZER IQ MODULE (CM-RC-02) for retrofit in existing systems. The three kits can be used to retrofit various applications in order to increase efficiency, avoid downtime and visualise data. All this with minimal effort for the existing electrical cabling – further upgrades are possible at any time.

(last revision: 09.2025)

For all semi-hermetic ECOLINE reciprocating compressors for HFC and HFO refrigerants as well as for ECOLINE PRO compressors for hydrocarbon refrigerants.

Retrofit for ECOLINE P compressors (order date until Nov. 2024) on request.

(last revision: 09.2025)

- Connectivity Kit: Contains CM-RC-02. Introduction to intelligent compactor protection with data recording and visualisation.

- Safety Kit: Contains CM-RC-02, oil heater, discharge gas temperature sensor, oil monitoring. For reliable oil management and optimum operational safety.

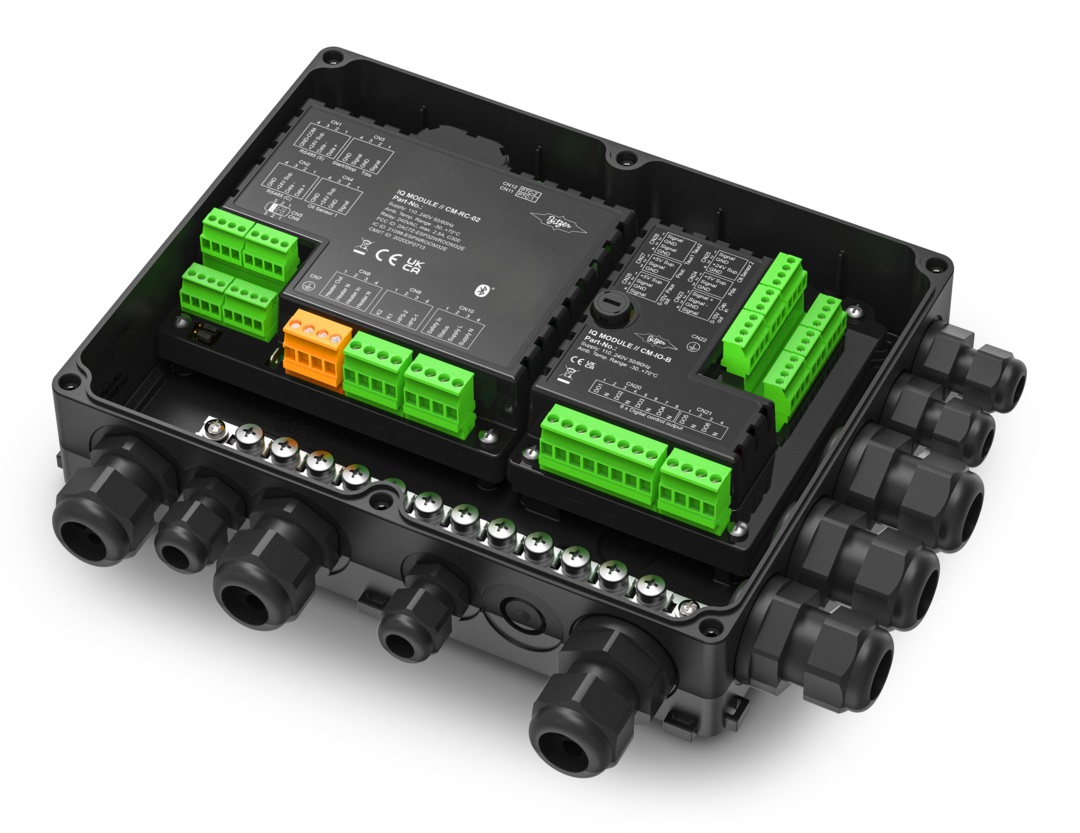

- Energy Kit: Contains CM-RC-02, extension board CM-IO-B, discharge gas temperature sensor, pressure transmitter and (depending on the compressor) two or three VARISTEP capacity regulators for mechanical capacity regulation. This allows for significantly higher efficiency in part load operation, i.e. lower energy consumption and higher COP/EER.

(last revision: 09.2025)

The retrofitting of the Performance Kits is described in the video tutorial KW-242. It also explains how to first remove the existing compressor protection device, install the CM-RC-02 compressor module and peripheral devices, and connect them to the BEST SOFTWARE. This requires BEST SOFTWARE version 2.21, which is available for download free of charge.

(last revision: 09.2025)

The motors differ e.g. in supply frequency and nominal voltage and have different starting characteristics (e.g. direct-on-line, part winding, star-delta start).

For details on starting modes see Technical Information AT-330.

Which voltage versions of the motors are available for different nominal voltages of the supply networks for which compressors is listed in the Technical Information documents KT-410 (reciprocating compressors), ST-410 (screw compressors), EST-410 (scroll compressors).

(last revision: 05.2025)

The available schematic wiring diagrams are compiled in the Technical Information AT-300. Some diagrams can also be found in the respective Operating Instructions or Technical Information.

(last revision: 05.2025)

Download the BEST SOFTWARE (also available as app: Android App, iOS App).

(last revision: 05.2025)

A continuously updated collection of information and documentation is accessible here.

(last revision: 05.2025)

The compressor protection devices SE-E4 and SE-E5 are certified according to UL 60730. The predecessor protective devices SE-E1 and SE-E2 are certified according to UL 508.

For details on protection devices see Technical information CT-120.

(last revision: 05.2025)

The CM-SW is available for all OS.A85 compressors incl. the booster versions (OSKAB85).

For details on the CM-SW see Technical information ST-150.

(last revision: 05.2025)

For OS.A85 compressors, the IQ MODULE CM-SW supports start unloading (CR 25%), stepped capacity control (CR 50/75/100%) and operation of the external motor with frequency inverter.

For details on the CM-SW see Technical information ST-150.

(last revision: 05.2025)

Capacity control with VARISTEP and the CM-RC enables a high switching frequency of the solenoid valves for capacity control (blocked suction) between 10% and 100%. This ensures that the controlled values, temperature and pressure fluctuate only little. Together with the wider capacity control range, this increases the efficiency of the systems.

The control characteristic for the optimum control of the solenoid valves is stored in the CM-RC, you only specify the set point in the form of a 0 .. 10V signal or a Modbus value.

For details see Technical information documents KT-240 (IQ MODULE CM-RC) and CT-310 (Modbus).

(last revision: 05.2025)

The operating time is not fixed. It depends on the operating conditions and the operation of the compressor in the last 15 min. The hotter the compressor, the shorter the possible operation at 10%.

For details on the IQ MODULE CM-RC see Technical information KT-240.

(last revision: 05.2025)

A PC with the BEST Software can be connected to the frequency inverters via the BEST interface converter. The adapter cable required for this has been supplied since 2021 and can also be ordered separately (part no. 344 311 05).

For details see Operating instructions CB-110.

(last revision: 05.2025)

Many BITZER compressors and condensing units can be controlled with the BEST SOFTWARE. The IQ MODULES CM-RC and CM-SW, the SE-i1 protection device, the compressors of the CSV. series and the controllers of ECOSTAR and ECOLITE condensing units have integrated Modbus RTU interfaces.

For details see Technical information CT-310 or BEST SOFTWARE.

(last revision: 05.2025)

In the models LHV7E, the suction gas cooled .F3 frequency inverters were replaced in 2023 by air cooled VARIPACK frequency inverters (model FOY+39-4, IP66). The model designation changes from LHV7E/ .. .F3 to LHV7E/ .. .F. Application limits, frequency ranges, refrigerating capacity etc. remain unchanged. From the outside, only the ventilation slot in the weather protective housing of the ECOSTAR is visible.

This change does not apply to ECOSTAR models with .F1 frequency inverter.

For details see Operating instructions KB-203.

(last revision: 03.2023)

Yes, every ORBIT compressors be operated with a frequency inverter. Depending on the application, frequencies of 35 .. 75 Hz are possible – with certain limitations at high condensing temperatures.

For details see Technical information EST-420.

(last revision: 05.2025)

Yes, BITZER offers a configurable, pre-programmed heat pump controller (LMC320). It is designed for domestic heat pumps, incl. brine/water, water/water and domestic hot water, ensuring energy efficient heating and hot water supply.

For details see BITZER website.

(last revision: 05.2025)

Weitere FAQ speziell zum IQ MODUL CM-RC-02 sind hier zusammengestellt.

Your question has not been answered? Get in contact!