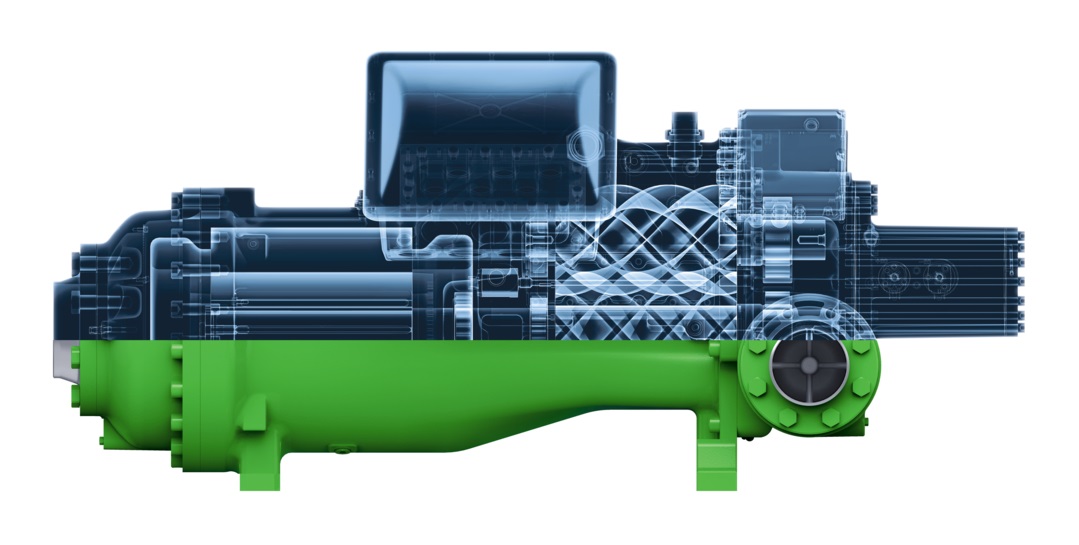

Screw compressors

The code letters "K" and "N" indicate the application range:

HSK: air conditioning and medium temperature application

HSN: low temperature application

OSK: medium temperature application

OSN: low temperature application

In some cases (e.g. OS.A74) there is also the code letter "H": air conditioning and heat pumps.

Due to the different application ranges, certain additional connections (e.g. economiser, refrigerant injection, oil cooler, oil and gas return) are available for some models.

For details see brochures SP-100 (HS.) and SP-500 (OS.).

(last revision: 05.2025)

The letters "H" and "W" indicate the application range (for CSH usually wider than for CSW), which can be further differentiated depending on the motor version and compressor design.

CSVH and CSVW are the corresponding speed controlled models with built-in frequency inverter.

For details see brochure SP-170.

(last revision: 05.2025)

If a BITZER compressor is no longer available, it can often be easily replaced by a current model. The most common cases are compiled in the Technical Information AT-310.

(last revision: 05.2025)

For flexibility in system design, BITZER products are available with a variety of different connections and shut-off valves. The available bushes, flanges, shut.off valves etc. are listed in the Technical Information AT-320. This document also explains which pipe fits which brazing or welding connection.

(last revision: 05.2025)

The models HSNP74 and HSNP85 are approved for operation with R290 and R1270 .

For details on operation with R290 and R1270 see Technical information AT-660.

(last revision: 05.2025)

The series HSK.53 .. HSK.85 (K and N models) are designed with a fixed internal volume ratio (Vi).

The HSK.95 compressors, on the other hand, are equipped with a double slider with variable Vi

range. The built-in CM-SW compressor module optimises the Vi automatically, allowing the HS.95 to achieve maximum efficiency under all operating conditions.

For details see brochure SP-100.

(last revision: 05.2025)

With speed-controlled part load (frequency inverter), ECO operation is feasible in most cases.

With mechanically controlled part load, ECO operation is possible in principle with some compressors, with others only near full load or not at all.

For details see Technical information ST-430.

(last revision: 05.2025)

The compressor protection devices SE-E4 and SE-E5 are certified according to UL 60730. The predecessor protective devices SE-E1 and SE-E2 are certified according to UL 508.

For details on protection devices see Technical information CT-120.

(last revision: 05.2025)

The CM-SW is available for all OS.A85 compressors incl. the booster versions (OSKAB85).

For details on the CM-SW see Technical information ST-150.

(last revision: 05.2025)

For OS.A85 compressors, the IQ MODULE CM-SW supports start unloading (CR 25%), stepped capacity control (CR 50/75/100%) and operation of the external motor with frequency inverter.

For details on the CM-SW see Technical information ST-150.

(last revision: 05.2025)

BITZER products are equipped or available with different oil monitoring systems. The available devices and options are listed in the Technical Information AT-170.

(last revision: 05.2025)

Your question has not been answered? Get in contact!